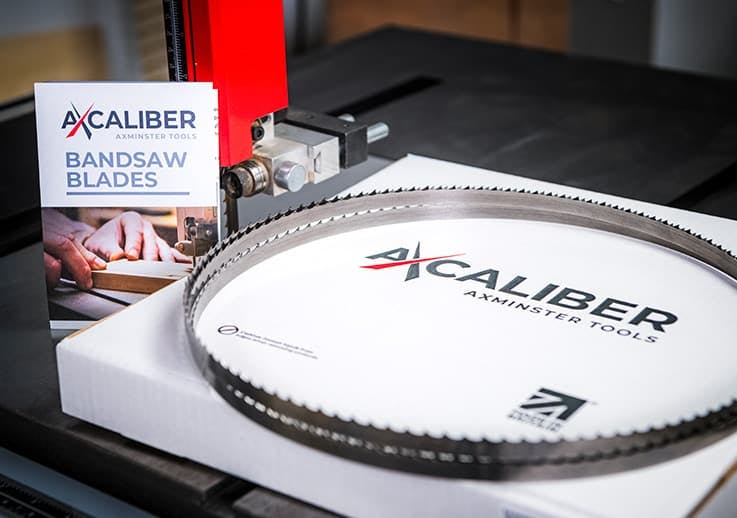

Axcaliber Bandsaw Blades

Whatever your blade, Axcaliber has a high quality, UK made blade for you!

UK made from start to finish

Quality Material

Rolled, carbon steel banding from a Coventry rolling mill has teeth either milled or diamond ground, in a purpose built factory in Featherstone, Yorkshire.

Durability

Next the banding is subjected to a hardening and annealing process to give durability to the teeth.

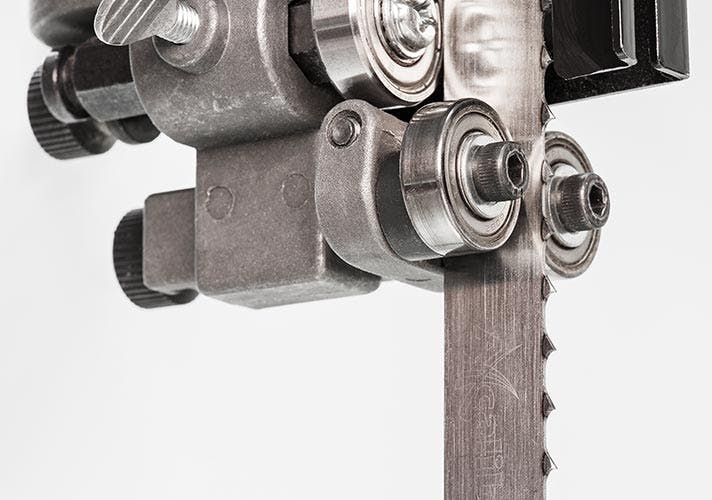

Accuracy

The banding is then checked for straightness on the back, using a special machine to correct any deviation that is out of tolerance. It is then packed and despatched in 100m reels to form the raw material for the bandsaw blades.

Manufacturing

Finally, at our own production facility here in Axminster the material is sized, welded, finished and packed in recyclable cardboard packaging, ready to be despatched to our customers.

Watch our in-depth overview of how Axcaliber Bandsaw

Blades are made

Axminster Expert Craig Steel talks through the production and manufacture of Axcaliber bandsaw blades. Manufactured in Axminster, using advanced CNC machining and specialised heat treatment, Axcaliber offers a wide range of high-quality bandsaw blades designed to meet all requirements.

Bandsaw Blades Types

Ground Tooth

Unique to Axminster, these blades are made from a material designed for the production user. The diamond ground teeth stay sharper for at least 30% longer and are so sharp that they give an exceptional finish and clean cut in almost all materials.

High Carbon

Best described as general purpose blades, these are suitable for many standard tasks in the workshop.

Premium

Made from M42 high speed steel with 8% cobalt, these blades will cut all materials with ease, even metal at the right blade speed!

Back Tooth

With small teeth on the back of the blade that clear the back of the cut by widening the kerf, these blades enable a much tighter curve to be cut, making them perfect for the woodturner wanting to cut their own blanks.

Ripper 37

Fitting only the largest machines with the motor capacity to handle them, these blades are specifically manufactured for wood processing and deep ripping tasks.

Freshcut 37 GT

These blades also have the diamond ground teeth, as well as a light teeth set and hook configuration. These culminate in a blade made for all ripping tasks, that will last for far longer than normal milled tooth blades.