Axminster Woodturning Clubman SK100 Chuck Package

Axminster Woodturning Clubman SK100 Chuck Package

Key Features

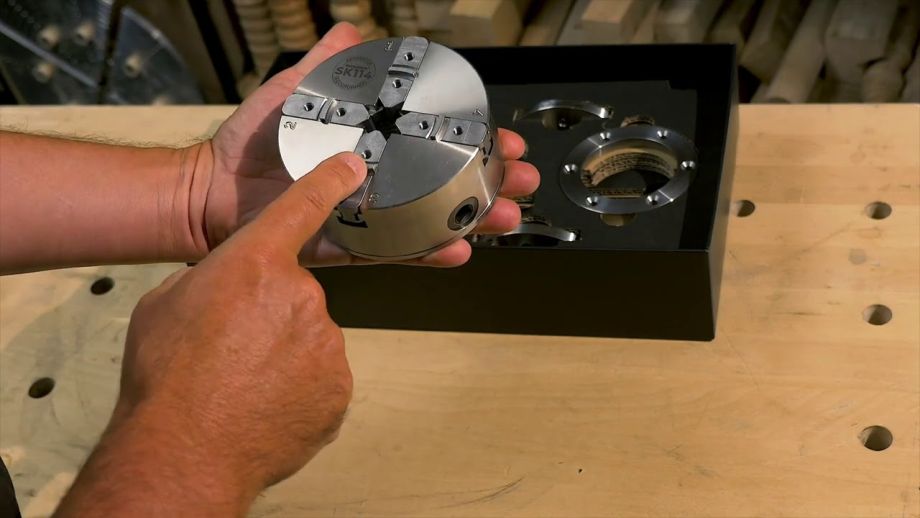

- Direct threaded chuck body ensures concentricity

- Fitted with the latest SafetyJaw© accessory mounting jaws

- Stainless steel for maximum corrosion resistance

- Includes C dovetail jaws, faceplate ring and screw chuck

- 100mm (4") diameter

- 5-year guarantee

- Made entirely in Axminster, England

- View full description

Customers Also Viewed

More than thirty-five years ago, Axminster produced and marketed one of the world’s first four jaw self centring chucks for woodturners. Over the years, much of the development has come from the feedback and input of professional woodturners. With over three decades of experience in production and design, we believe these latest chucks are the very best on the market today. Manufacturing of the Clubman chucks, jaws and accessories is done entirely in our production facility here in Axminster.

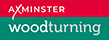

This kit gives you the ability to mount blanks for initial turning all the way through to the final completion of a well-executed project. It includes carefully chosen accessories offering a great deal of woodturning potential.

Our CNC production technology ensures your chuck is as accurate and reliable as possible. The 100mm (4") stainless steel chuck body including the thread is a single piece, maximising concentricity and minimising vibration during use. The SK100 features our latest SafetyJaw accessory mounting jaws.

This starter kit includes a set of easy to use dovetail jaws (size C), into which you can also mount either the matching faceplate ring or the screw chuck.

All you need to do is choose the chuck thread to suit your lathe.

Made entirely in Axminster, England.

N.B. Thread options M33 x 3.5mm and 1.1/4" x 8tpi have an extended body with provision for reverse locking.