The Art of Scroll Sawing (Part 4)

Welcome to part four of The Art of Scroll Sawing blog.

A few people have asked me to give an overview of scroll saw blades in my previous post comments, so this week I will be reviewing the range of blades by Pegas.

Pegas Scroll Saw Blades

Pegas scroll saw blades are right up there alongside the best blades available on the market and are produced in Switzerland to a very high standard. Anybody using the scroll saw will enjoy using these high quality blades and good blades make for easier working!

Below you will find my breakdown of all the current available Pegas blade types and some of their applications. I've also taken the time to explain your options a little further in the following video:

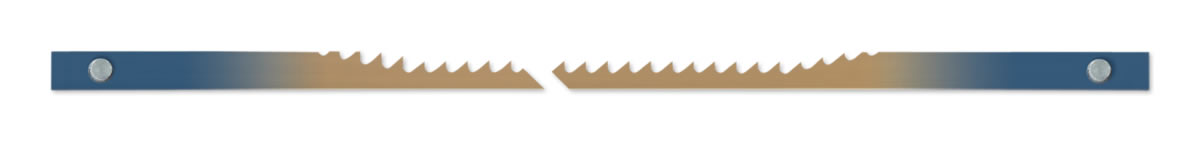

Pegas Pinned Blades

Pinned blades are generally a lot more coarse than pinless blades and they have a much wider kerf. These are ideal if you are trying to cut straight lines, however they are not very good for doing internal fret work because of the size of the blade. Also in this range, you have hook teeth blades that are pinned and cut extremely well.

Key features

- Easy to fit, 127mm(5") pinned blades

- Suitable for many materials

- Best carbon steel, made in Switzerland

- Packs of 6

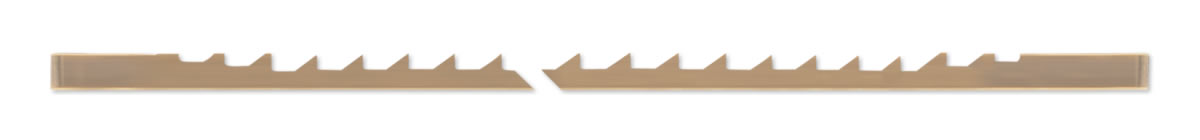

Pegas Skip Tooth Blades

Skip Tooth blades come with various tpi. These are great from the respect of cutting different materials according to the tpi. If you are cutting more hard wood than softwoods then go for a coarser tooth blade. They are called skipped blades because they have a tooth then a space then a tooth and so on. With these blades the teeth always face down towards the table.

Key features:

- Performs well in wood, plastic, bone, Corian® and most fibrous materials

- Allows the cutting of intricate patterns

- Heat treated high carbon steel

- Versatile, suitable for many materials

- Excellent chip removal, fast feed rate & smooth finish

- Blade length 130mm

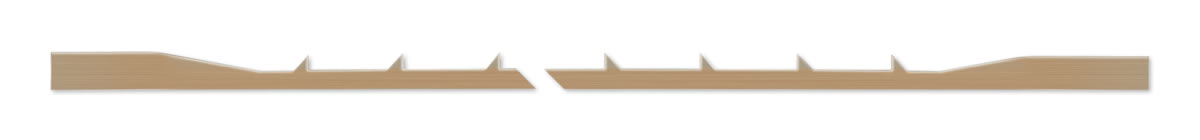

Pegas Reverse Skip Tooth Blades

Reversed Skip Tooth blades are the same as skipped blades except they have around three quarters of the blade facing down towards the table and about a quarter facing up underneath the table. The idea being that they cut both sides of the wood giving you a cleaner cut top and bottom on the work. Reverse teeth prevent splinters from developing on the underside of the workpiece because the top teeth do not cut entirely through the work. They have various tpi and are also available in double skip reverse to help clear more debris from the cut.

Key features

- Reverse teeth prevent splinters on the underside of the work

- Versatile, suitable for many materials

- Various sizes & tpis

- Blade length 130mm

Pegas Modified Geometry Teeth (MGT) Blades

Modified Geometry blades are probably my favourite blades of all . They are the same as skipped reverse except that they have more spacing between the teeth so they do not heat up as much. These blades are great on lower set speeds for cutting materials such as acrylics, from the respect that they do not heat up. They are also great for cutting hard woods.

Key features:

- Tooth design minimises burning

- Use on soft and hard wood up to 75mm thick

- Also well suited for plastic

- Accurate pattern cutting leaving a very smooth finish

- Blade length 130mm

Pegas Spiral Blades

Spiral blades are great for doing intricate fret work as the blade cuts 360°, however these blades are not so great if you are trying to cut straight lines as they will want to wander off course.

Key features:

- Helical design offers all round cut

- Heat treated high carbon steel

- Blade length 130mm

- Work does not have to be turned to make cuts

- Excellent for wood, plastic, metals, bone, wax and more

Pegas Metal Cutting Blades

Metal Cutting blades are great for people wanting to cut non-ferrous metals, such as jewellery or coins, using their scroll saws. They have a much finer tpi and with the right tensioning on the blade they cut very well and very clean.

Key features:

- Various sizes & tpis

- Heat treated to give maximum performance with power scroll saws

- Use in scroll saws or hand frames

- For precise cutting of thin metals up to 3mm

- Blade length 130mm

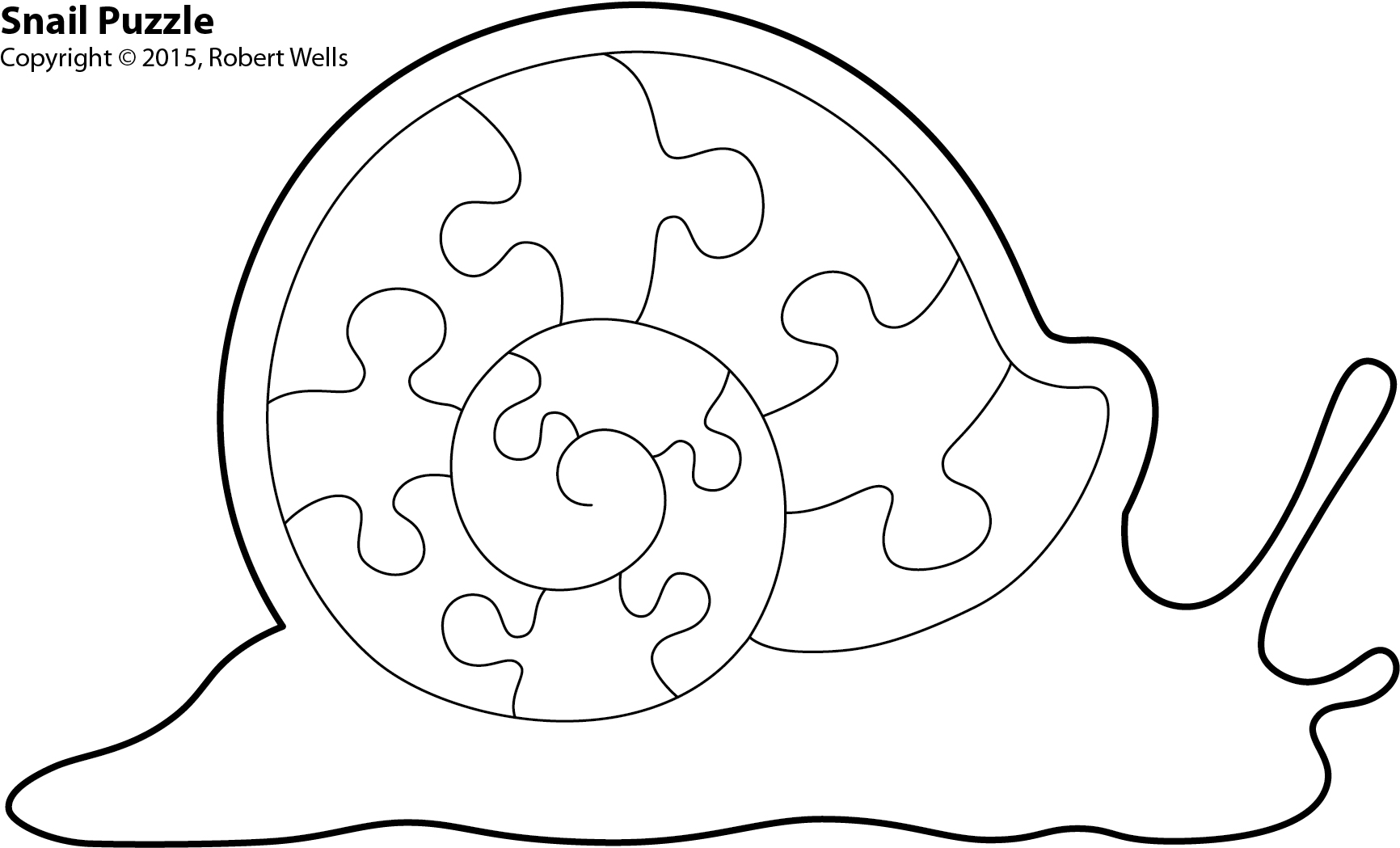

Pattern of the Week

Another excellent pattern from Robert Wells for you this week that hopefully won't prove too slimy when cutting the intricate shell! As with the elephant puzzle and the polar bear puzzle featured previously, this is best made with a good hardwood like beech and a backing panel can be added to securely hold the puzzle pieces in place.

Click the image above to view the full size pattern and save to use as a template for your project. Thanks again to Robert and please do let us know if you decide to give this pattern a try and as always I'm happy to answer any of your questions in the comments below!

This is probably a stupid question, how do you transfer the image from a pattern to the wood surface in preparation for cutting on a scroll saw or do you just stick the paper on the face!

Hi Ron,

No stupid questions! Basically you can print the image off or photocopy it and then i always use masking tape to put onto the wood and then glue the design onto the wood. When you finish the masking tape just peels off and you don't have to use much abrasive to finish the item. Hope that helps!

Thanks,

Adrian

I use stick and spray from crafters companion. It is designed as a temporary adhesive in paper crafting. It works brilliantly, I spray it onto the back on the pattern then place that onto the wood. It comes off fine and leaves no residue. I also use it in stack cutting, spreading both sides of a bit of paper, sandwich that between the wood and there is no slip.

Where is my post. I put a message up with a picture of my snail. I also asked when you would be posting again Adrian.

Hi Stooby,

It doesnt look like your message posted correctly? Can you try again? I'd love to see your picture of the snail! You should be able to attach an image to your comment (click the little icon of a picture and select the image on your computer to upload). If you're still having difficulties I can give you my email address to send it to?

I'm currently working on some new posts to come in the near future so keep a look out!

Take care,

Adrian

Great news Adrian. Here i my snail. I made him from pine as it was all I had to hand and needed to make a present in 2 days. I used teak oil, again if I had longer I would have spent a little more time on the finish. The present was for my sister, 36 and lifeline snail lover. She loved it and kept playing with it.

They are great as they are so handleable and can be stood up as well. I'm going to give the bears and elephants a go at some point as well.

Thanks Adrian.

Sorry Adrian that didn't work again can you let me know how I email you?

Hi Adrian I have the 18 inch axminster trade and a joy to use it is here are a few photos of the commissions I have done on it

Hi Adrian I have an 21" Excalibur scroll saw I have had it for a couple of years now I have done all the setting up and checked everything I can but the only problem I have is vibration if you take the speed control as a clock, at about 2 o clock I get quite a heavy vibration at 3 o clock it goes away at 4 o clock onwards the vibration gets so bad it breaks a No3 blade I have got the saw on a very heavy stand with filled drawers, (too heavy to lift) I feel it is some sort of imbalance either on the motor counterweight or maybe on the linkages I was wondering if any of your readers have had the same problem and if there is any solution, Can't find any solution on the net any help would be appreciated .

Thanks Bryan

Hi i am just starting out any tips on how you cut the inside of the puzzle with out cutting through the outside part of the puzzle. It doesn't seem you can drill a hole through the inside of the puzzle. Any tips cheers