The Resourceful Woodworker focuses on one-on-one routing with UJK router bushes

To round off this short series on the UJK Technology Router Bushes, I’m going to look at how to produce a simple curved form which will fit exactly into a corresponding shape; what’s known as ‘one-on-one’ routing which under normal circumstances is impossible to achieve because the diameter of the cutter will always produce a curve with a slightly different radius.

For example, ‘one-on-one’ routing is needed when applying the lipping to an elliptical table with an mdf base. The base can be machined relatively easily but the lipping needs to have exactly the same curvature as the substrate in order to mate precisely. This can be achieved using a series of bearing guided cutters, but the sequence of cutters and bearings required is somewhat tricky to work out...I was once shown many years ago and if memory serves, there were around eight or nine different stages for the order in which the cutters and bearings had to be used.

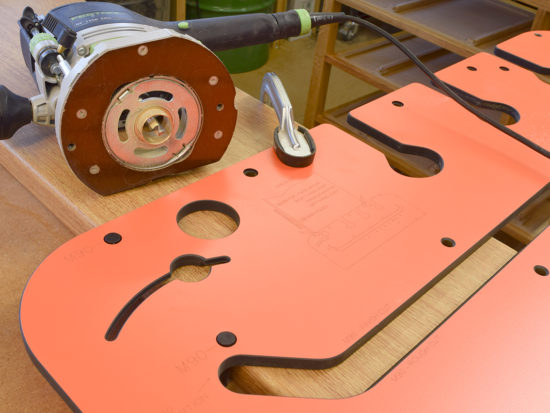

When using the UJK Technology Bushes, the process is still complex, but easier to understand with these simple steps and some pictures.

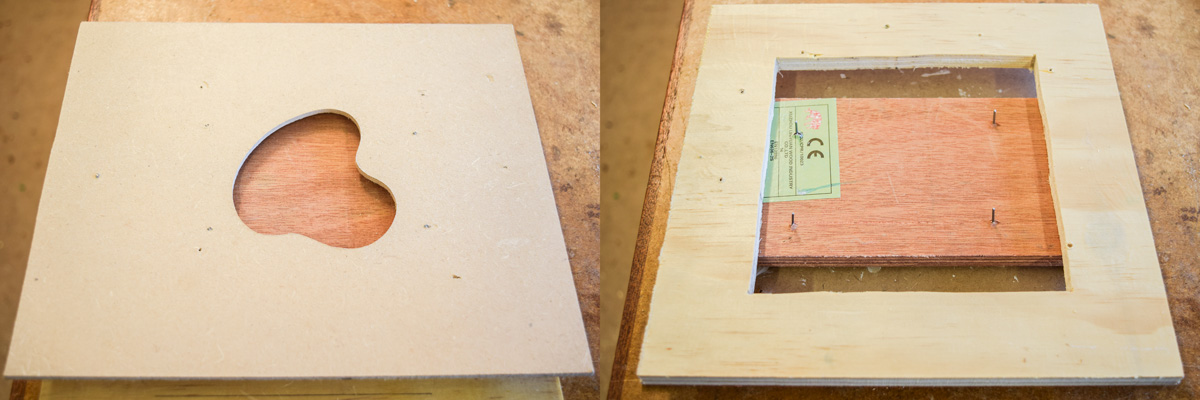

Step 1: the first thing to do is to prepare the base from an oddment of 12mm ply and cut out a big hole in the middle. This raises the whole job so that when the router is plunged through, it won’t damage the bench.

Step 2: the template is then prepared. I marked a simple curved shape, cut it out with a coping saw and then smoothed the edges with a Proxxon mini drill with a sanding attachment in the chuck. The first blank is then placed over the square hole in the base, with the template on top of that, together with some 6mm ply spacers underneath to give clearance, which in effect forms a four layer ‘sandwich’. The whole lot is secured with several brads from a nail gun so that it’s now ready for the first pass with the router.

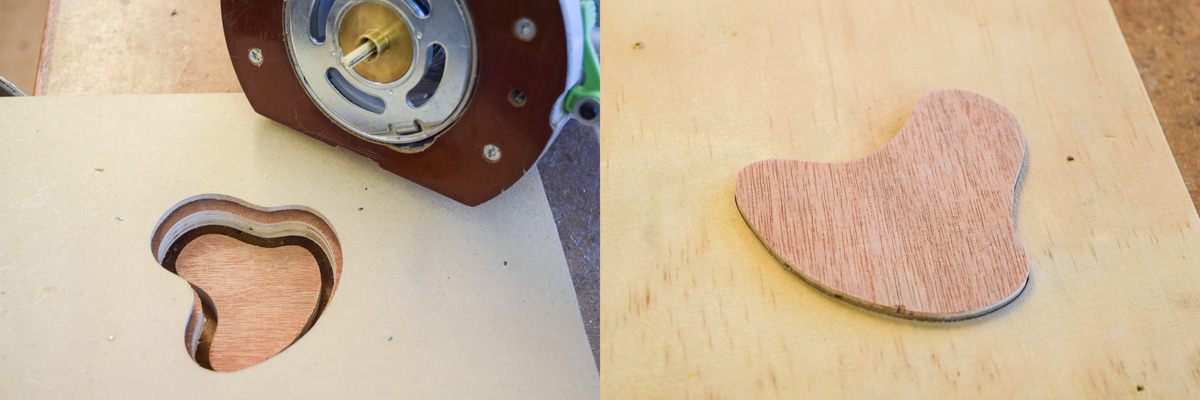

Step 3: a 6mm cutter is installed in the router collet, together with a 24mm bush, giving an offset of 9mm. Once the cut has been completed, the centre waste section will drop through onto the workbench top.

Step 4: removing the nails and taking the jig apart leaves the first blank (arrowed) with the curved hole in the centre. The second blank will now be routed to fit this hole.

Step 5: the second blank, in this case a piece of red 12mm mahogany ply, is mounted in exactly the same way as the first blank. The second image shows the underside and four of the securing brads.

Step 6: the 6mm cutter is retained in the collet but the bush is now changed to 12mm giving an offset of 3mm. A second pass with the router is now taken and again, the centre section will drop onto the workbench. However, this in NOT the waste and once the whiskers have been sanded off it will fit exactly into the hole produced in the first blank!

Cute or what?