Turning Small Components On The Lathe

Most workshops ought to have a lathe of some sort, not only for the pleasure of turning bowls and other items but for the occasions when components need to be made for other projects.

Turning small components on the lathe can be dangerous, mainly because they are too close to the chuck. As a result, there’s a danger that hands and the tool may foul the rotating chuck. If this happens, the results may be very painful, rather expensive or both. In this particular instance, the parts needed are a few, very small turned drawer pulls in ebony.

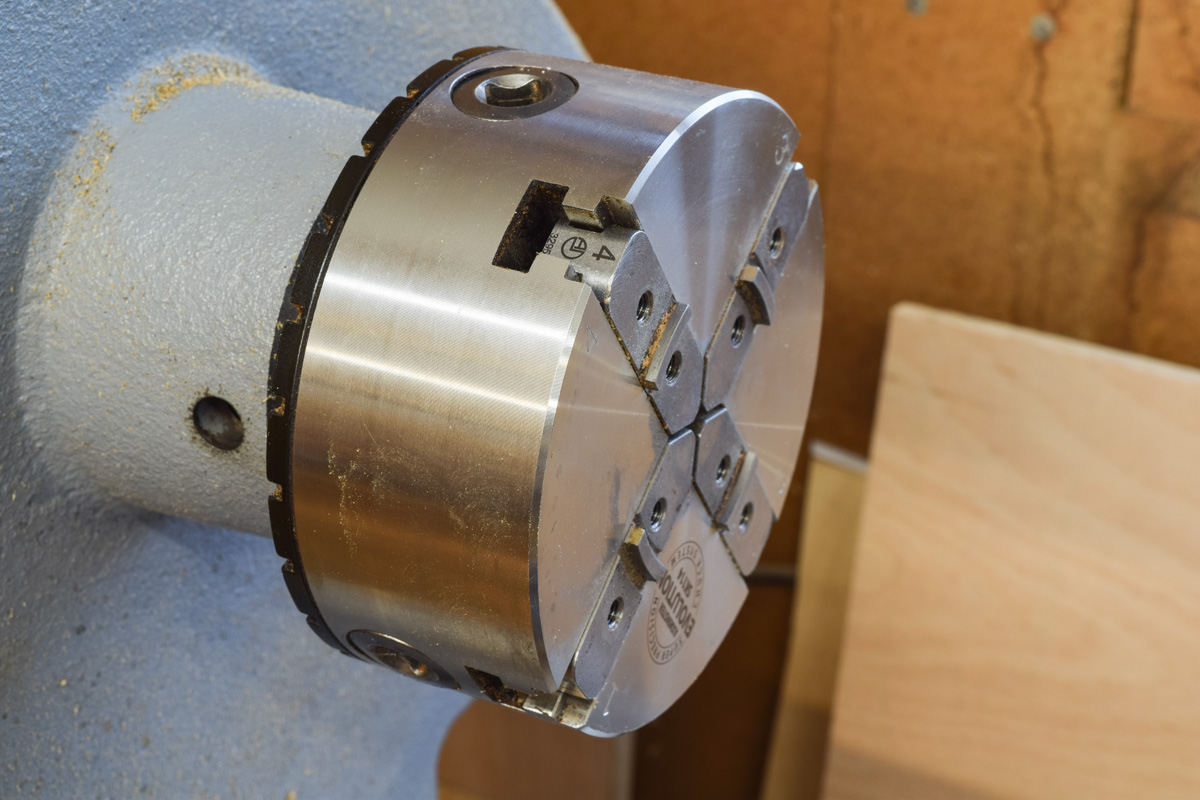

The VS1628 lathe and the Evolution SK114 chuck are specified; however, the basic principle outlined here can be used with any machine.

What you'll need

Step 1

The standard Axminster Evolution Long Accessory Mounting Jaws as supplied with the SK114 chuck are designed so that other jaw sets can be mounted on them. As a consequence, turning small components is awkward if the project is small as the operator’s hands and turning tool are too close. The jaws must be taken out and replaced with an alternative set.

Step 2

Replace the jaws with the Internal Jaw set. This provides extra clearance when turning very small items such as a tiny drawer pull.

Important!

Each jaw and it's corresponding position in the chuck is clearly numbered. Ensure that the jaws are inserted into the chuck in the correct sequence.

Step 3

It’s now much safer to turn small components close to the rotating chuck with less danger of snagging the tool or the operator’s hands.