Treating The Back Of A Japanese Chisel

It has to be said that I’m a big fan of Japanese tools, in particular the Japanese chisel. They are, compared to their western counterparts, a ‘learning curve’ and don’t suffer fools or abuse gladly. The reason is the blades are composite, made from a super hard cutting steel and a much softer backing iron. This provides the chisel with flexibility for use at the bench on a daily basis.

Japanese tradition

Centuries ago, and even today, Samurai swords are made in a similar way. A harder cutting edge is forged on to a much softer iron core.

The very hard (often around RC65) cutting steel, is always forged, resulting in a close grained molecular structure enabling an unbelievably sharp edge.

Like most good things in this world, there’s a downside. The hard cutting edge is extremely brittle, much more so than a western chisel. If a Japanese chisel is used to lever out waste, it’s almost certain to result in a chipped edge. This would require extensive sharpening to restore it.

Differences

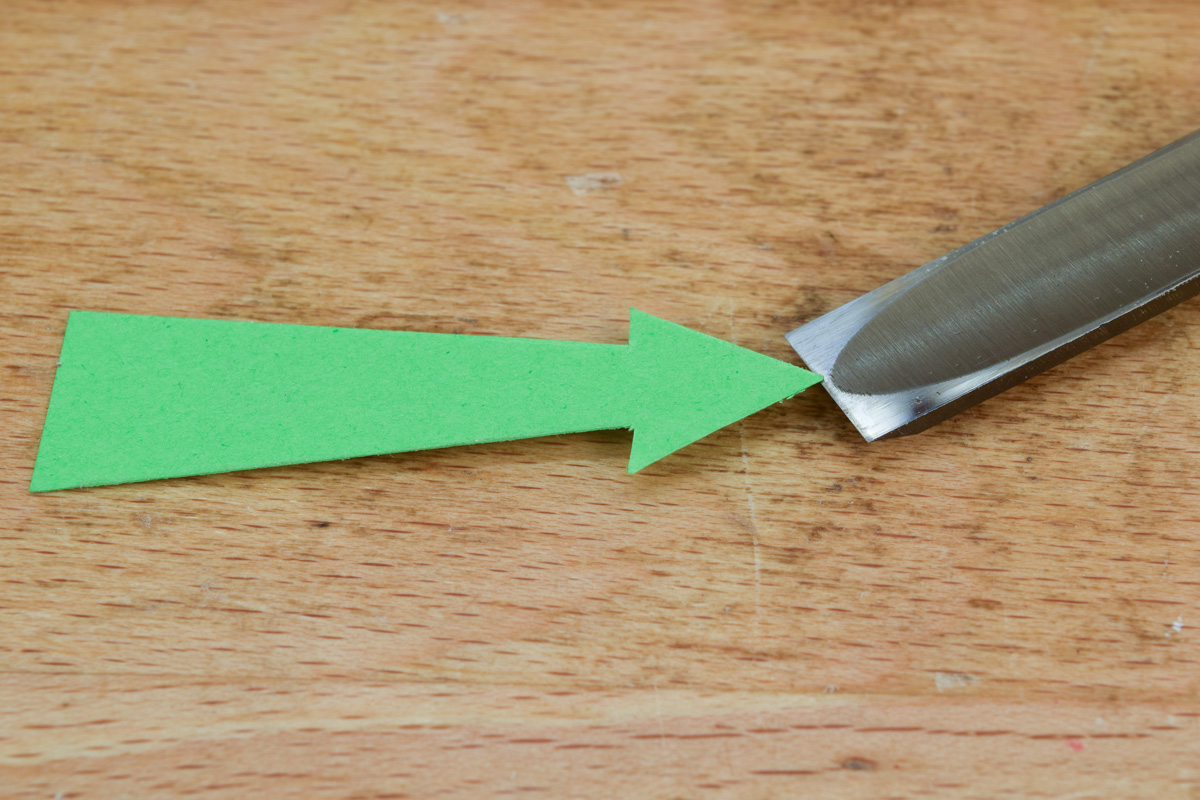

One other glaring difference between a western and Japanese chisel, is that the back has a long depression ground into it. And it’s there for a very good reason. The back of a Japanese chisel still needs to be flattened, and even more so if there’s a slight bump behind the cutting edge. The depression or ura* (arrowed) reduces this area of very hard steel in contact with the sharpening medium, and thus reduces the time taken to work on the back.

Were there to be no ura (as in a western chisel), the unfortunate owner would be standing at the sharpening station for a very long time.

It can also be seen from the same chisel, that the distance from the cutting edge, to the start of the ura (arrowed), is around 0.5mm, which is not very much.

After repeated honing, the edge will move backwards and begin to eat into the ura. Therefore, the ura must also be moved backwards by flattening the back on waterstones.

Using Japanese chisels is a constant process of honing the bevel and polishing the reverse side. This is so the ura is always a few millimetres away from the edge.

They do eventually, after much use, also turn into butt chisels.