Axminster Woodturning Button Jaws - Woodturning Tools

Button Jaws, also known as Cole Jaws, in all their forms are most commonly used for reverse chucking. The jaws feature eight conical white rubbers which are designed to hold a turned piece firmly but gently against the aluminium jaws plates. This allows you to make any changes to the exterior surface of your turned piece.

Button Jaws

In this helpful article, we cover everything you need to know about our Axminster Woodturning Button Jaws.

What is Reverse Chucking?

Reverse chucking is the method of re-mounting your turned piece onto the lathe in order to finish the exterior of your project. Typically the last step, the method can be used for a variety of tasks. It is ideal if you need to remove marks left by the chuck, as well as if you need to remove the tenon or recess that was used to hold the piece while turning the interior of the bowl. What's more, it is also useful if you plan to add decoration to the external side of your project.

How Button Jaws Work

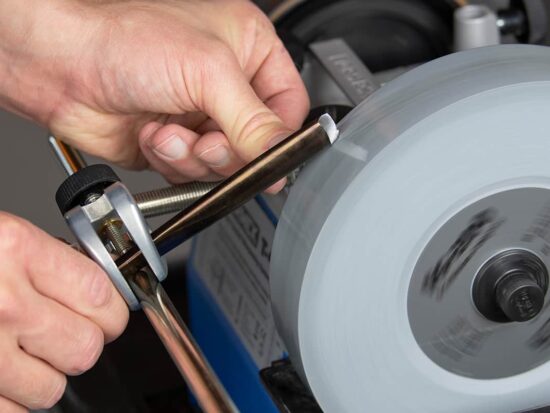

Firstly, button jaws work by gripping the workpiece firmly but gently between the eight conical rubbers. As well as the tapped holes, there is a slot in each of the jaws which allows the position of the jaws to be finely adjusted to accommodate slightly irregular pieces. These jaws can take bowls up to 225mm in diameter.

As an alternative to using the buttons, stacking turn studs are available as an optional extra. These are designed as a primary holding device for all manner of round or square blanks. They provide a very secure holding method and can be used singularly or doubled up using the longer bolts supplied.

Conveniently, the Axminster Woodturning Button Jaws are suitable for the SK100 and SK114 chucks. As with all our dovetail jaws, they simply bolt onto the Accessory Mounting Jaws.

Finally, although the rubber buttons are easy on the wood, they are not particularly suitable for bowls with a very fine edge. In such a case, a better alternative would be specific wooden jaws mounted on Axminster Woodturning Wood Jaw Plates. For better access, a longer chuck key may be required when using button jaws.

Discover more...

Did you enjoy this article about our Axminster Woodturning Button Jaws? If so, why not explore some more of our interesting and helpful articles. Firstly, the Special Edition 50th Anniversary SK100 Chuck by Axminster Woodturning is the latest addition to our chuck system range. Bringing with it all of the same, superior qualities and unique features as its big brother, the Evolution SK114 Chuck, the SK100’s smaller 100mm diameter size allows it to fit comfortably in the palm of your hand. This makes it easier to handle and manoeuvre and allows it to fit on smaller lathes.

Next, holding your work correctly on the lathe is a crucial part of ensuring you get the best results for your woodturning project. But, with so many woodturning chucks, jaws and accessories to choose from, it can be a daunting decision to know which is right for your project. In this helpful series of videos, Jason talks about all things jaws.

Finally, from their manufacture, through to the major advantages of each jaw, Jason helps breakdown the woodturning system to give you a better understanding of which woodturning jaws you need for the work you’re doing.

Get in touch!

If you love the Axminster Woodturning brand, we’d love to hear from you. Comment below or send us a photograph and tell us all about your recent purchases or favourite tool. Alternatively, get in touch via our social media platforms. Find us on Facebook or connect with us on Instagram using #axminsterwoodturning to @AxminsterTools.