Axcaliber Router Cutters

Exceptional performance with incredible value

These top quality router cutters are produced using advanced technology on up-to-the-minute multi axis CNC machinery. Shanks are made from SAE4140 steel hardened to Rockwell 45RC, renowned for its hardness and strength, and the tips are made from diamond ground micrograin tungsten carbide. A polished finish ensures a durable, clean cutter capable of holding a sharp edge and a thick PTFE coating enables the cutters to remain free of resin.All cutters are produced with high shearing angles.

A comprehensive range

The Axcaliber router cutter range covers a wide variety of applications with cutters ranging from the tiny 3mm single flute cutter up to the 75mm diameter panel raising cutters. To ensure safety, each shank is clearly graduated to indicate how far you should insert the cutter into the collet of your router.

View all Axcaliber Router CuttersHow are they made?

1) The Steel

All Axcaliber TCT router cutters start life as a plain, cylindrical blank of SAE 4140 Chromium-Molybdenum, high tensile steel. Hardening and tempering to RC45 offers an ideal combination of strength and toughness along with abrasion and impact resistance.

2) Turning

State-of-the-art CNC machines turn the plain billet of steel into the profile required for a particular cutter. The process ensures absolute precision to close tolerances for every cutter.

3) Milling

The third step in the production is to CNC mill the flats and recesses. The shape of the finished cutter now starts to emerge.

4) Carbide Tips

The preparation of the cutting tips is critical. Axcaliber router cutter tips use 99% pure, micro-grain, C2 or C3 tungsten carbide. This is characterised by its high strength, toughness as well as extreme hardness. Its hardness falls between 8.5 and 9.0 on the Mohs scale, almost as hard as diamond.

5) Brazing

Once the tungsten carbide tips are ready, brazing onto the tool steel body can commence, using high frequency machinery. This process is critical as router cutters often rotate at over 20,000rpm.

6) Sand Blasting

Sand blasting removes any flux residue from the brazing process, as well as other contaminants, leaving a pristine, matt surface.

7) Coating

The cleaned cutter now gets a smooth, even, surface coating of PTFE. One of the outstanding properties of this material is that very few solid substances can adhere to this coating. The coating effectively minimises resin and heat build-up on the cutter.

8) Grinding

At this stage, the cutter is almost complete. The shank and carbide cutting faces are now precisely CNC diamond ground to their final profile. This leaves a smooth, virtually mirror polished finish on the shank, whilst the carbide tips gain an extremely sharp edge. Once grinding is complete, next comes the process of dynamically checking for balance.

9) Assembly

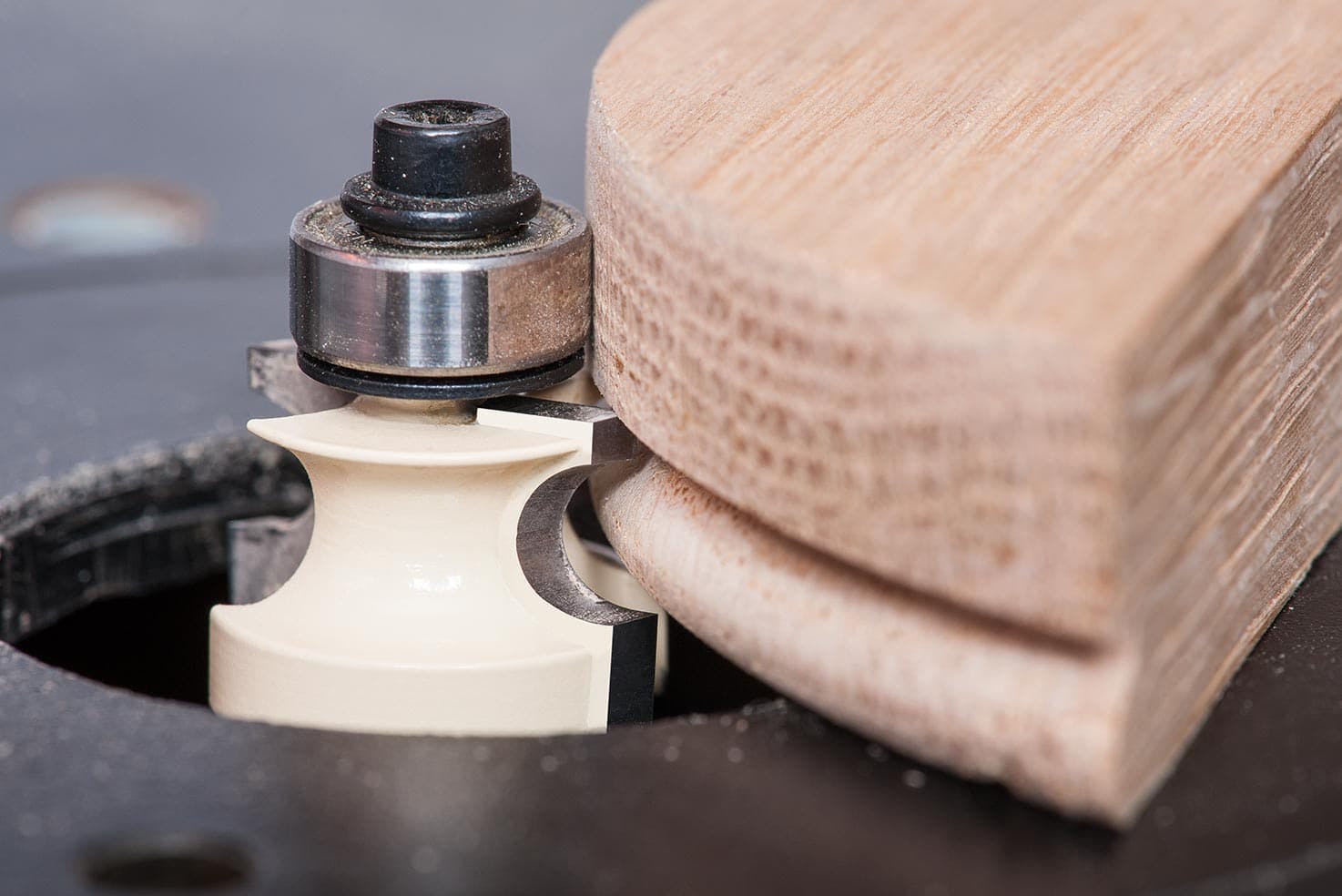

If required the fitting of a bearing takes place. The shank is laser engraved with size, maximum speed and diameter. Graduation marks on the shank, indicate the optimum, safe insertion depth into the collet of the router.

10) Packaging

Axcaliber router cutter packaging is a rigid, transparent, plastic container with printed details. This serves to protect the carbide edges from damage as well as making a convenient method of storage and easy identification in the workshop.

General Tips

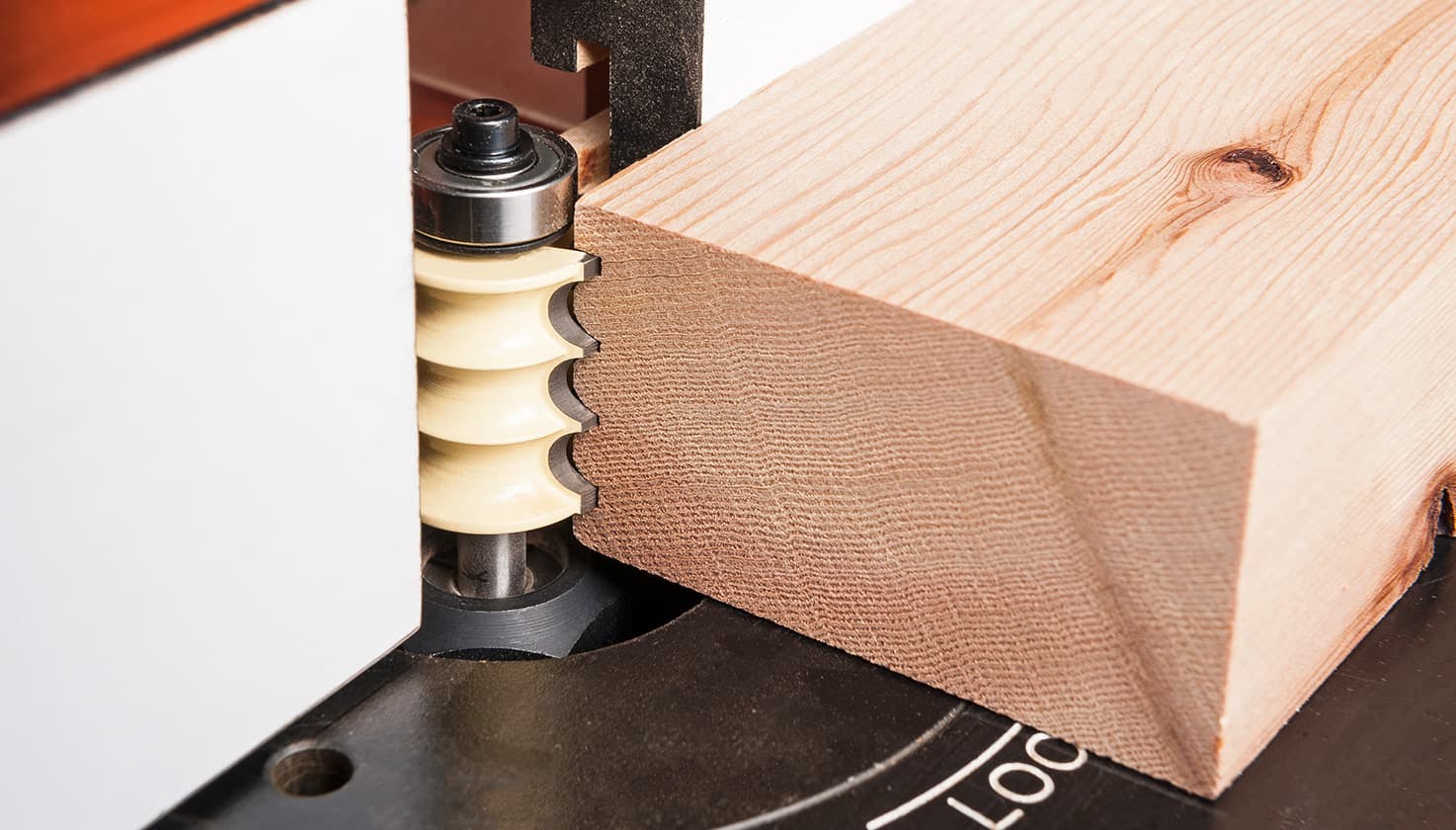

Most of this is common sense. In answer to the question of how much material should you remove with each pass? Three thin shavings are better than one thick holds true. You need to keep the stress on the cutter and your router to a minimum. Plunge cuts with ¼" shank cutters; remove between 3mm and 6mm depending on the material. The harder or more abrasive the material the shallower the pass should be. Long cutters, such as those used for jointing kitchen worktops, can create excess side load when cutting too deeply in one pass. Take 10 to 12mm per pass until you reach the full depth.

If possible use a cutter of a similar length to the depth of cut required. That way your cutters will last longer as no one part of the edge is doing all the work. Make your last pass as light as possible, just a final whisker to leave as clean a surface as possible.

Watch Axminster expert Jason Breach demonstrate how easy it is to use the Axcaliber stile & rail cutters with a panel raising cutter to make a door. He also explains how this is not just for making doors, but a jointing system that can be used to make much more.