What Sharpening Stones To Use

What Sharpening Stone To Use?

A new, or even experienced woodworker may be forgiven for finding the whole area of sharpening stones confusing. With so many different types available it becomes very difficult to know where to start. This buying guide will primarily examine the stones sold by Axminster. But, at the same time, will briefly explore some of the many alternative stones which the craftsperson might consider.

Natural or Synthetic Sharpening Stones?

All sharpening stones can be placed into two categories. Either natural, having been quarried from the ground, or synthetic, having been been manufactured. Before the industrial age, all sharpening stones were natural by default. Simply picking up a piece of common sandstone and stroking it along a sword blade may have been enough to produce an edge. This would at least remove some of the worst nicks and gouges produced by the clash of steel.

How Do Sharpening Stones Work?

Any stone is composed of particles of abrasive material that are bonded, or sintered together. The blade is passed across the stone, the steel is worn away, thus creating the edge. However, at the same time, the stone is also worn away to reveal new, coarse particles. As a general rule, the softer the stone, the more rapidly it will wear and will be more aggressive in use. Harder stones don't wear as fast. Over time, the edges of each particle within the stone tend to become slightly rounded. Particle size may be smaller, although the finished edge is very sharp, it takes much longer to hone the blade.

Grit Size

Sharpening stones are graded by the size of the individual particles, or grit. In an artificial stone they are all the same. The grit falls through a sieve with a predetermined mesh size. Stones are also categorised in terms of 'microns'. The classification can be a little confusing. Generally, a 220g stone corresponds approximately to a particle size of 60-80 microns A 1,000g stone is 15-25 microns. A 1 micron is roughly equivalent to a 10,000g finishing stone.

Synthetic Sharpening Stones

The sharpening stones sold by Axminster are all synthetic and comprise mainly of two main types; water and diamond stones.

Water Stones

Synthetic water stones are relatively new in the West. But natural ones have been the main choice of sharpening media in the Far East for centuries, particularly in Japan. This particular type of stone consists of abrasive particles which are sintered together using a very friable clay material. In use, the clay starts to disintegrate which produces a thin, slushy surface on top of the stone which is saturated with sharp particles; new abrasive grit is continually produced as the sharpening process takes place.

In general terms, the stronger the bond, the slower new abrasive particles are released and the slower the cut, but the stone will remain flatter for slightly longer. The reverse also applies; the looser the bond, the more rapidly the stone cuts and eventually a hollow in the surface is produced.

Grits

Water stone grits vary from a 240g, very coarse surface all the way up to a 10,000g superfine finishing stone. Generally a 4-6,000g stone will produce a finished edge suitable for everyday work. The coarser and medium grade stones should always be kept ready for use under water either in a special stone pond or in any sort of shallow plastic tray. They are then retrieved, complete with their holder and are ready for use at the bench. Fine and superfine stones can be stored dry, but need to be sprayed with water just before use. A small Nagura stone is also supplied which is used to build up a polishing slurry on the stone or to deglaze a used surface.

There are three different makes of synthetic water stone currently on offer. Firstly, the general duty King stones, made by Ice Bear and available in grit sizes from 220 to 10,000g. Secondly, those manufactured by the Sigma Power Corporation in Tokyo, designed specifically to cope with sharpening high alloy steels. These ceramic stones have a very fast cutting action and will release new, aggressive particles in use. However, they will wear slightly faster. Thirdly, we have Bester, manufactured by Imanishi in Kyoto, Japan. Their particle bond is moderately strong and will quickly cut O1, A2 and PMV-11 steel. They'll remain flat for just as long as a slower cutting stone, with a stronger bond matrix.

Flattening Waterstones

One of the issues with water stones is that they will wear into a hollow very quickly. Although they cut rapidly and are capable of producing a super fine edge, they should be flattened every time they're used. This can be done in a variety of ways but the best method is to use a dead flat ceramic block over which the waterstone is rubbed. Alternatively, the DMT Dia Flat Lapping Plate is guaranteed to bring a hollow water stone back to pristine condition, as shown in the video clip below:

The final method, which is more economical but perhaps not quite so accurate is to use a piece of float glass onto which has been stuck to a sheet of 180g Aluminium Oxide paper. Whichever method is chosen, using and flattening waterstones is a messy business and it's a distinct advantage to have access to a sink and running water.

Diamond Sharpening Stones

Diamond stones offer one alternative to traditional sharpening stones and provide many advantages, the principal one being that they will remain dead flat, even after sustained use. A matrix of pure, monocrystalline diamonds is permanently bonded to a dead flat, nickel plated steel substrate. These stones are available in a wide variety of different formats, for example, double sided, bench whetstones, handled mini-hones or even credit card sized diamond plates to fit conveniently in your wallet!

They are now offered in a very wide range of grits from extra, extra coarse 120g - 120 micron up to extra extra fine 8,000g - 3 micron. The initial cut with diamond stones is very aggressive but this disappears after a while as the stone 'beds' in. Some types of stone have a pattern of circular or oval holes across the surface and this is intended to carry away the sharpening swarf more easily. A little more care should be taken with continuous diamond stones, particularly the finer grits as the surface is liable to clog more quickly. Diamond stones can be used without any lubrication, but it's generally recommended to use either water (make sure to clean and dry it afterwards), a light machine oil or WD40.

Axminster Rider Sharpening Station

The recent introduction of the Axminster Rider Sharpening Station utilises the Axminster Rider Double Sided Diamond Bench Stone and a top quality Connel leather strop, both set in a phenolic plastic board. There's a 'step like' area at each end that's been machined out of the phenolic surface. Each step has been engraved 25°, 30° and 45°. They're intended to be used with the Rider Honing Guide to ensure that the correct, repeatable honing or grinding angle is achieved every time the blade is sharpened. You can watch Jason Breach take you through sharpening with the Axminster Rider Sharpening Station, along with other sharpening methods.

'Scary Sharp'

Though not strictly a sharpening method using stones, the so called 'scary sharp' technique has become increasingly popular in recent years. At it's simplest, a sheet of fine 400g abrasive is stuck to a dead flat piece of float glass and the blade, usually held in a honing guide, is sharpened on the surface. From that simple idea, the system has evolved so that it's now much easier to apply the abrasive as a whole range of very fine, self-adhesive Hermes Aluminium Oxide papers are readily available. Lubrication is still required to float away the sharpening debris and either a fine machine oil, water or even WD40 (or similar) can be used.

'Scary sharpening' is very economical; when the paper becomes worn or ineffective, simply rip it off and stick on a new piece. The system is also very popular because like diamond stones, there's also no danger of the sharpening surface becoming hollow.

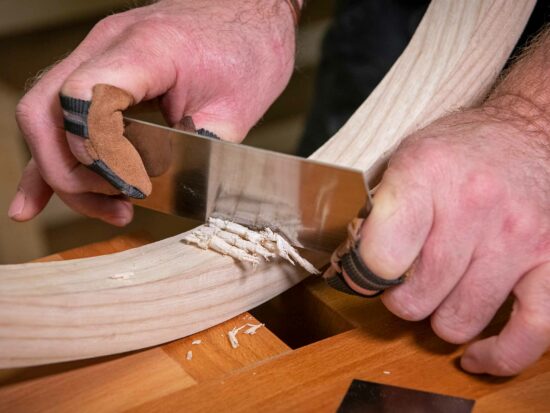

Stropping

For centuries, traditional barbers offering a wet shave used (and still do) a leather strop to produce a super fine edge on a cut throat razor and this sort of technique can be used to very good effect on plane and chisel blades. The leather is dressed with a lubricant of some sort (machine oil, petroleum jelly or similar) and then a very fine abrasive paste is rubbed into the surface. When the blade is pulled (never pushed) over the strop several times, the effect is to continuously refine an already sharp edge; precisely what the barber is hoping to achieve on his razor.

Natural Sharpening Stones

Natural sharpening stones are those that are quarried from the ground as a crude slab of rock, then cut to size to adopt the familiar rectangular shape. At one time, these were the only sharpening stones available and there were many different types, most of which were in use locally in the country where they were produced. Natural stones are still available and command a premium price, for example, Arkansas stones from the USA.

Translucent stones are classified as Extra Fine and may be a shade of white, grey or even pink. Black Arkansas are Ultra Fine being black or blue-black in colour and the finest edge can be achieved with these stones.

Natural Japanese waterstones are still available, though nearly all quarries are closed. However, there still exists a large quantity of mined stone. Quarries containing the finest stones have all but been exhausted. If one were to be found, it would cost a fortune. Even so, similar, less than perfect stones that are currently produced can still fetch well in excess of €400!

Conclusion

Sharpening is a basic prerequisite for any woodworker, without a fine, honed, edge, nothing much is liable to happen. Instead, the craftsperson is likely to be hamstrung by their inability to make progress. But, once that elusive edge is found by using a sharpening system, there's no limit to what can be achieved. It's been said before, but 'sharp fixes everything'.

Would you like to learn more? We offer a range of sharpening courses at the Axminster Skill Centre.

Hi, I purchased the Axminster Rider sharpening station last month, I also bought the the recommended lapping/ lubricating fluid too. I have sharpened a total of three woodworking chisels and I’m not convinced that the diamond grit has all but worn away? The first chisel, you could tell was sharpening well, but now the stone seems very lack lustre? Have you any thoughts?

Hi Paul, thanks for the comment. I'm sorry the stone isn't working as it should. Please can you contact our customer service team cs@axminster.co.uk and they will arrange a replacement stone. Thank you.

Hi Folks, Is there any place where one can find actual the grit size (in Microns) of the various pastes - I use the Veritas green polish stick which is listed by Veritas as 0.5 micron size and definitely produces a nice polish on my chisels and planes (and my cut-throat, which is my only razor) using strops - but Axminster does not seem to publish this grit size - as mentioned in your notes the actual sizes of stones is fraught with confusion (and marketing hype) - if the real grit size was published (in Microns) this would reduce the confusion for some of us at least. For those of us who fully appreciate very high degrees of sharpness, see Rob Coseman's comments on CBN wheels in YouTube.