You can never have enough clamps

Our latest range of clamps meet the exacting requirements of the trade

The Axminster Trade Clamps range includes clamps for use in woodwork, engineering and fabrication or welding. We are able to offer top quality clamps which are all suitable for trade use. With thoughtful design and construction from excellent materials, they represent exceptional value. Especially when you take advantage of our Bulk Discounts, meaning the more clamps you buy, the cheaper they become.

View the range

"We are so confident Axminster Trade Clamps will never let you down we’ve given them a Lifetime Guarantee!"

The Axminster Experts

Active clamping and clamping pressure

Active Clamping

Active clamping is when a forged steel clamp maintains its pressure regardless of the condition of the timber. For example, if a piece of timber, with a relatively high moisture content were to be clamped in a warm workshop for an extended period, there’s every chance it would shrink. As the timber contracts, the force applied to it will remain constant as the forged clamp frame will actively move with the timber. Equally, the pressure applied with a standard drop forged clamp will decrease as the timber shrinks.

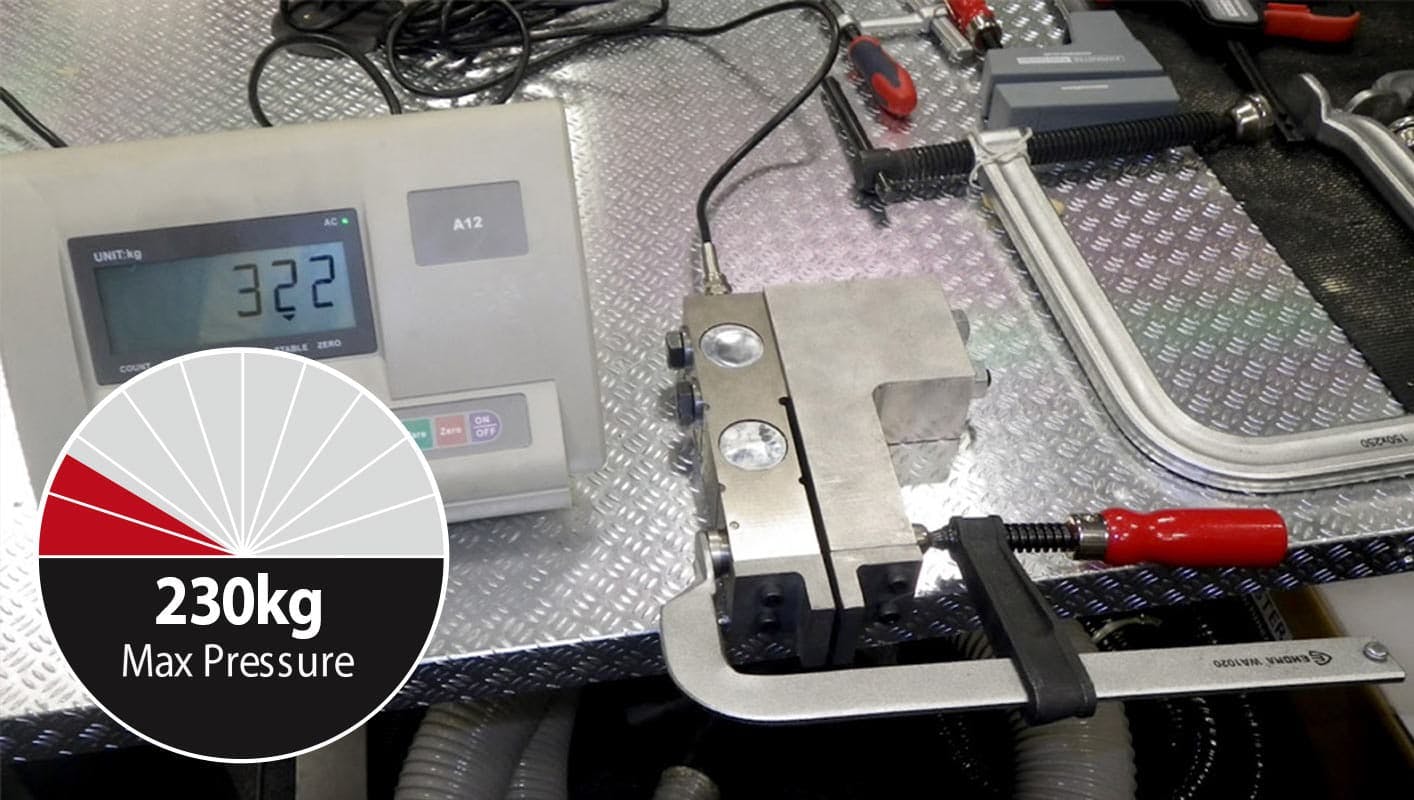

Clamping Pressure

Clamping pressure is a new feature throughout the Axminster Trade range of clamps, each clamp is accompanied by its maximum clamping pressure. How were these figures achieved? Each clamp pressure was measured using a load cell machine, giving us its maximum pressure in kg. Each figure can easily be converted into Newtons, where 1kg is equal to 9.8 Newtons.

What are our clamps made from and why?

We stock a large range of clamps that come in a large variety of materials. Steel in one form or another predominates. So why use one type of steel rather than another? Clamps in particular exert considerable force. The clamp has to withstand these forces without breaking, bending or permanently deforming. A clamp that fails under load or ends up distorted is no use to anyone.

Axminster Trade Clamps are all made from the finest materials, both the materials and processes which we have used to obtain the best results are highlighted below.

Cold Drawn Steel

This is generally used when referring to the bars of sash and F clamps. Hot rolled steel bar would be cheaper and easier to use. However, steel bar reduced at room temparature by pulling (drawn) through an oil-lubricated die is superior in many ways.

Cold working changes the properties of the metal, importantly giving it greater tensile and yield strength. The dimensions are easy to control with tolerances at least five times more accurate over hot rolled steel. There is guaranteed consistency and straightness. Pulling the bars through the die, orientates the grain within the metal. It becomes harder and the surface finish improves.

Forged Steel

Forged steel has many advantages over cast iron. Weight for weight a forged steel clamp is far stronger than a cast or machined clamp. The grain is continuous throughout the structure, following the shape of the clamp. Hot forged steel is also not work hardened, allowing the use of a more controlled hardening process.

The forging process used to make our clamps uses an induction heating process. A combination of dies and presssings then create the required shape with a very high degree of accuracy. Induction heating can target an area that needs its shape changing, such as a bend. The strength and reliablity of a forged steel clamp gives it the ability to exert the maximum clamping pressure time after time, with no misalignment of the frame.

Ductile Iron

Where a casting is used, then ductile iron is a better choice. It has much greater impact and fatigue resistance over grey cast iron. It possesses high strength and resistance to shock. The improved mechanical properties increase its resistance to breakage from physical load or if accidently dropped onto the workshop floor. Its wear resistance is comparable to some of the best grades of steel and it is superior to grey iron. All this makes it an economical choice for many applications.