How To Use A Kitchen Worktop Jig

Fitting a kitchen worktop is a job that fills many of us with dread; they’re heavy, unwieldy and often need joining. Fortunately, the UJK Technology Worktop Jig makes a difficult job relatively straightforward, so that even a moderately competent user should have no trouble in making professionally fitted joints.

How Does The Kitchen Worktop Jig Work?

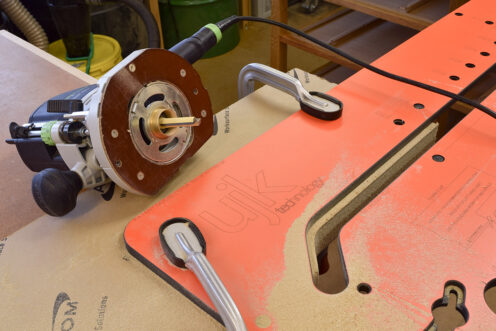

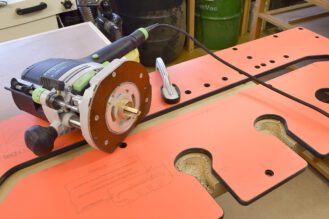

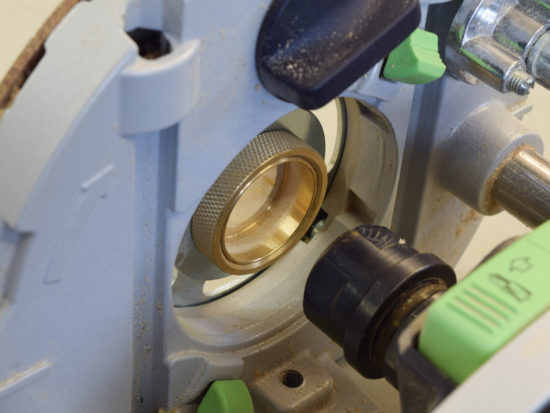

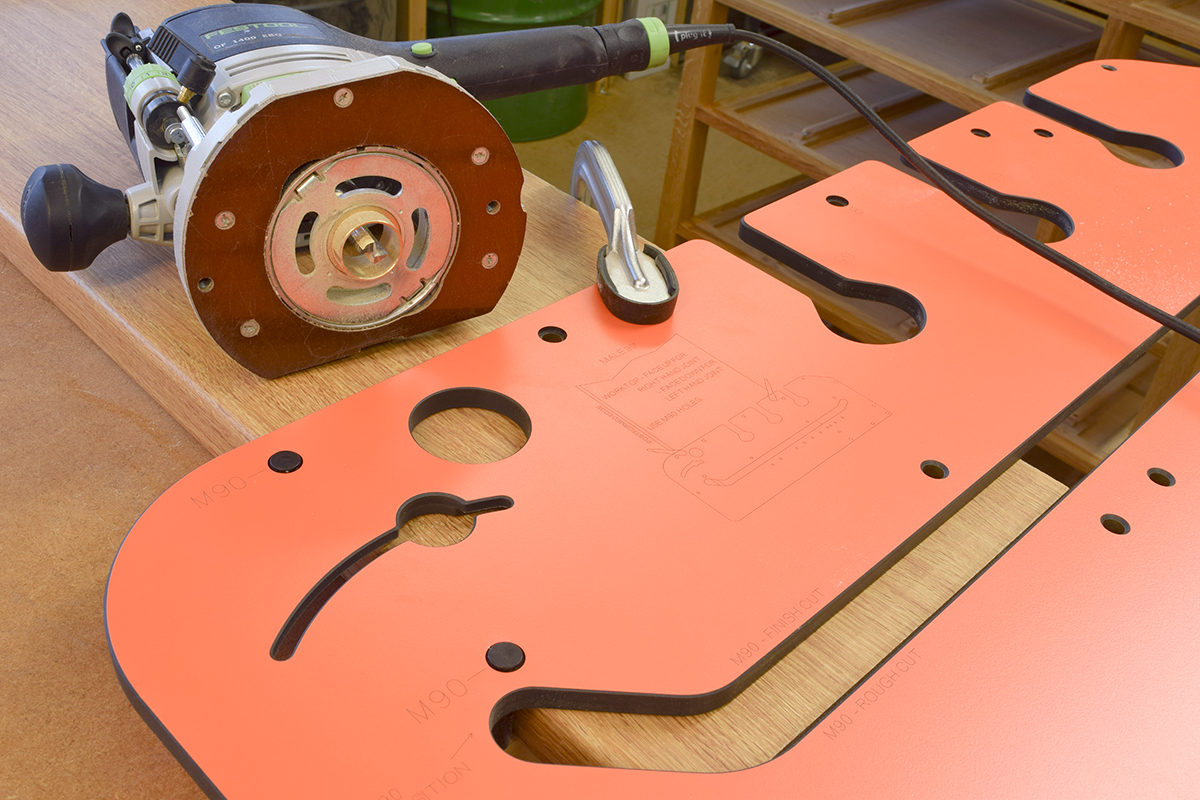

The manual supplied is excellent and please familiarise yourself with the concept of how the jig works. It’s made from a thick slab of phenolic resin, into which are various CNC machined slots and round holes. The slots are used for machining purposes and it’s into these that the 30mm guide bush and cutter fits. The jig comes supplied with four plastic pegs which fit into the holes and their positioning is dependent on the type of joint being made. The pegs serve to position the jig exactly in the correct place on the worktop and, once located, it’s held securely in place with the clamps. It’s worth noting that the jig should only ever be used when it’s firmly held with two clamps.

Once correctly clamped, the jig will produce male and female cuts for a number of joints including 90°, ’peninsular’ and 45°. A unique optional accessory (the Angle Adjustment Plate) will also fit the jig, allowing perfect out of square joints from 85° to 95° to be machined and fitted.

Normal worktop is 600mm wide; however for the purposes of this article, an offcut which measured 270mm wide was used.This presented some initial problems in using the jig as some of the locating pins couldn’t be positioned correctly; however the issues weren’t insurmountable and were overcome quite easily. The jig is designed to be used with worktops that are full size or a minimum of 300mm and, as such, these problems won’t occur.

What you'll need

Creating A 90° Left Hand Joint

Step 1

Position and clamp the jig to cut the female section of the joint.

Step 2

A worktop with a melamine surface and thick chipboard core present a challenge to any router cutter so it’s best to proceed with caution.

Take a series of small cuts until the waste piece falls away.

It’s also advisable to fit the dust extraction fitting to the router but this may obstruct the view of the cutter. If the extraction outlet isn’t fitted, use the shop vacuum after each cut to clear away the sawdust.

Step 3

To cut the recesses for the worktop connector bolts, position two of the pins in the location (arrowed) and take several small cuts to finish at a total depth of 20mm.

Step 4

Cutting kitchen worktop is very easy with a circular saw and ‘shop made ‘T’ square, make sure the worktop is ‘underside up’ so that the leading teeth of the saw blade cut through the melamine surface on the ‘up’ stroke.

Step 5

To cut the other half of the joint, position the jig across the end of the worktop and locate it with two pins in the M90 holes.

Step 6

Turning both pieces over, use a pencil to mark the position (arrowed) of the remaining connector bolt recesses. Using a narrow piece of worktop, it’s only possible to locate two of the pins (arrowed) but check the jig for the correct alignment by using a square across one edge.

Step 7

Machine the recesses and then cut the connector bolts to the correct length and assemble the joint

As this was for demonstration purposes only, no glue was used. However for a kitchen installation use a waterproof polyurethane glue before tightening the connector bolts.

Creating A Right Hand Variable Joint

When cutting a variable joint, it’s essential to study the manual to follow the correct procedure and ensure the worktop is the right way round. Cutting the female section of the joint is identical to the previous example, except that now you need to machine the worktop ‘face up’. Machine the connector recesses identically as in the previous example.

Step 1

Use a protractor to mark out the offset angle (5°) on the female section of the joint. This is the maximum setting of the Angle Adjustment Plate.

Step 2

As the pencil line is now at 85° to the edge, the circular saw and ‘T’ square can no longer be used. In which case it’s easy enough to cut the end true and to the correct angle using the jig. Using a 30mm guide bush and 12mm cutter, the offset is 9mm (30-12 / 2 = 9).

Step 3

Prepare a 9mm strip of timber and then use this to line up the jig’s slot parallel to the pencil line. Next clamp in place and make the cut.

Step 4

To cut the other half of the variable joint, bolt the Adjustment Angle Plate onto the jig and set to the offset angle of 5°. It’s vital to double check the cut will be in the correct place by visually examining the joint before cutting. Once satisfied, turn the worktop and jig over, clamp to the workbench and make the cut.

Step 5

Complete the recesses for the connector bolts, and then fit and tighten. You can then turn the worktop over. The large 300mm workshop square shown in the image emphasises the variable angle of the joint.

Cutting through chipboard and melamine can present a severe challenge for a router bit. However the long shank ½” cutter came through the experience with flying colours. After soaking for a few moments in Blade & Bit Cleaner, the cutter is still very sharp and capable of a lot more work.

Conclusion

Post formed kitchen worktops are difficult beasts to handle at the best of times. It’s well worth proceeding with some care when making joints in them. That said, the UJK Technology Kitchen Worktop Jig will make a variety of faultless joints with the minimum effort.