Fuji Spray | HVLP Spraying Tips

Whether it’s HVLP spraying or maintenance tips you're after for your Fuji Spray HVLP system, we’ve got you covered.

Here are a series of videos offering tips and advice to help you get the best out of your Fuji Spray HVLP system.

Viscosity and dilution

Viscosity is the measurement of a fluid’s resistance to flow. In order to determine how to thin your liquid ready for spraying, you will need to use a viscosity cup and time how long it takes to empty.

Stir your liquid thoroughly. Dip your viscosity cup into the fluid to fill the cup. As you remove the cup, start your stopwatch. When the cup has drained, stop the watch. Check the “run out time” on the Fuji Spray viscosity chart to see which air cap set best suits your material’s viscosity.

Liquids become sprayable when they have a runout time of 80 seconds or less through a 44 viscosity cup.

Check the side of your material’s tin or technical datasheet for which solvent to use to dilute. It is best to dilute in stages. Fuji recommends diluting at a rate of 10%. If, after this, you still have a run out time of less than 80 seconds, increase your dilution by 5% increments until it is in the sprayable range.

If your liquid is not diluted enough, you will get large spray droplets on the edge of your spray pattern. Over dilution and you’ll see small micro bubbles or craters in your finish.

Make sure to write down your viscosity run out times, dilution levels and which air caps to use to make future spraying sessions easier.

Choosing your air cap set

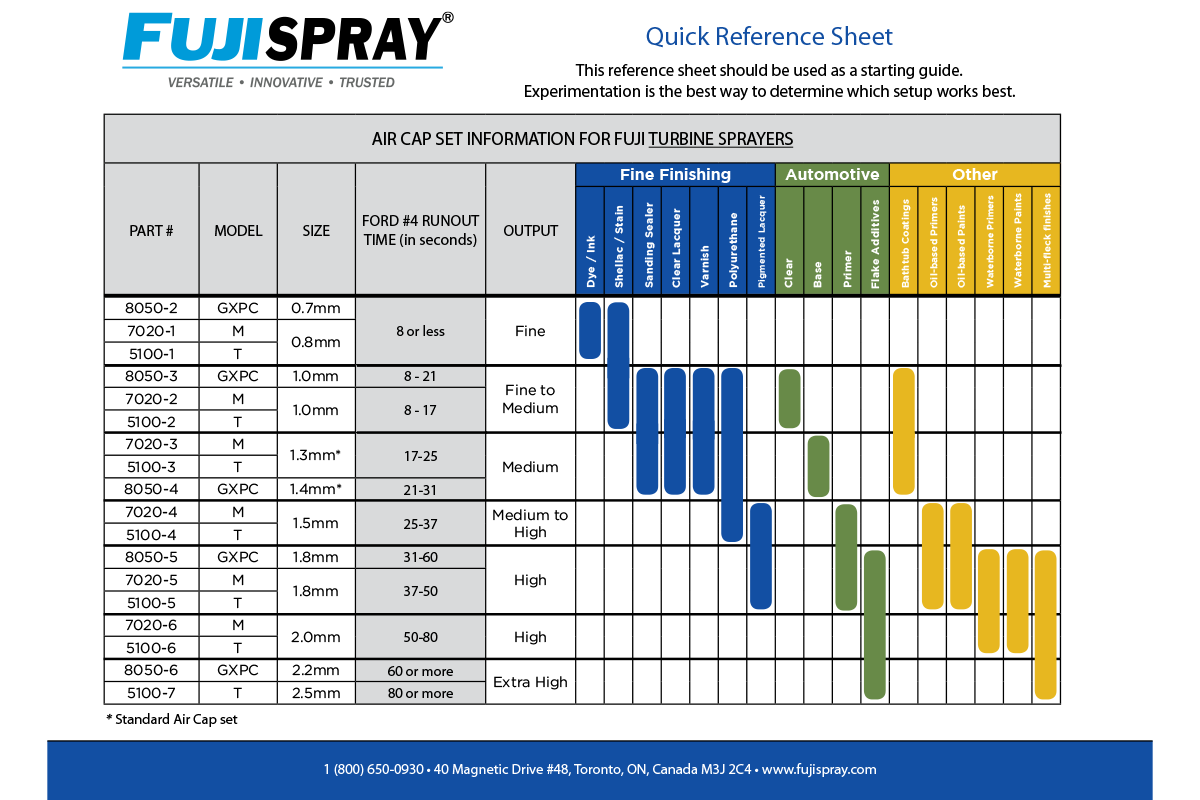

Fuji Spray’s reference guide is perfect for helping you choose the right air cap set for your job and finish.

Colour coded to include the finishing job and type of finish along with type and size of air cap set according to the viscosity run out time of your finish.

Fan pattern control

Controlling your fan spray patterns with a Fuji Spray gun is easy, with its incremental control. With a simple turn on the dial, take your fan spray pattern from a narrow 1 inch pattern to a 13 inch wide fan pattern.

GXPC - This features a side mounted pattern control. Turning the control dial increases and decreases the pattern control producing wider or narrower patterns.

T-Model - Features a patented side mounted control similar to the GXPC, however, the way the air is distributed inside is unique to Fuji Spray.

M-Model - This model features a rear mounted pattern control dial. While it doesn’t fully rotate as the others, it does still offer incremental pattern control.

Rotating the air cap will also help you adjust the fan pattern. Rotating the air cap horizontally gives a vertical spray pattern and vice versa.

Spray gun maintenance

Here are some top tips for keeping your HVLP system running at its best. Whether it’s a gravity feed gun, suction feed gun, entry level or professional series, regular cleaning and maintenance will keep your spray gun in tip top condition and give you years of use.

Clean your filters regularly

Make sure you clean or replace your filters on the turbine regularly. These filters are the first line of defence against debris and overspray from your turbine.

Keep your turbine away from your spray area

The key to keeping your turbine in tip top condition is to keep it as far away from your spraying area as possible.

Clean your spray gun

Regardless of which Fuji Spray gun you use, it will need regular cleaning. Use Fuji Spray’s 19 piece spray gun cleaning kit. It includes a variety of different brushes to get into those hard to reach areas. Use the lubricant in the kit to prevent your gun from seizing up.

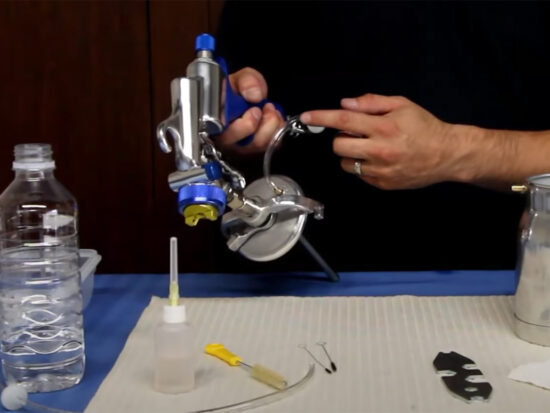

Pressure tubes and check valves

A clogged pressure tube will not be able to pressurise the cup preventing you from spraying. Have an extra set on hand so you can change and clean them easily.

Summary

Regular maintenance of your HVLP Fuji Spray turbine and spray guns, along with proper preparation, dilution and correct air cap selection, will give you exceptional HVLP spraying results every time.

I think this is wrong....If, after this, you still have a run out time of less than 80 seconds, increase your dilution by 5% increments until it is in the sprayable range..... should it say if run out time is more than 80 seconds......