When it comes to rust, prevention is better than cure

Rob Stoakley gives some sound advice on this subject

It’s that time of year again and no, I don’t mean Christmas, but that time of year when the clocks have gone back, the sky seems to be permanently grey and the dampness worms its way into every nook and cranny. If, like me, you’ve got a collection of half respectable tools and equipment that you’ve collected over the years, this is probably the most worrying period for keeping the dreaded rust at bay.

How can it be prevented from getting a grip and if it has, how can you eradicate it? Much of the answer to the first part of this riddle lies in how and where tools are stored.

A cold, leaky, condensation ridden garage, shed or outhouse is a prime suspect for harbouring rust and any ferrous surface left untreated in those sorts of conditions will show signs of corrosion fairly smartly. Improve the storage conditions and the chances increase drastically that your precious tools won’t degrade into stuff only fit for a rusty bucket at a boot fair.

My own workshop is fully sealed, with no drafts and is quite well insulated; the down side of course, is that it’s hotter than Hades in the summer. I have a 1.5kW oil-filled radiator on one of the walls, which I run off an electronic thermostat turned down to its lowest setting. The radiator takes up a small amount of space, is totally safe and provides a bare minimum of heat so that the workshop is kept constantly at around 50°F (or 10°C). This background warmth is sufficient to ensure that all steel and iron surfaces are kept in pristine condition all through the wetter, colder weather so that I’ve never had to make any serious attempts to keep rust at bay.

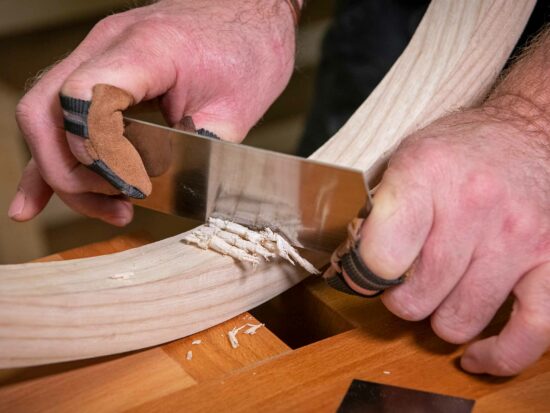

Prevention is usually always better than cure, so I adopt a ‘belt ‘n’ braces’ approach as well. Tools like planes and chisels are given a wipe of Camellia Oil at the end of each workshop session, which is excellent for providing a barrier to moisture. Cast iron machine surfaces are a little too big for Camellia Oil, but a decent coat of Liberon Lubricating Wax is reassuringly effective in preventing the first telltale bloom of rust. Apart from this highly desirable protective feature, it really is a ‘cure all’ and should be a mandatory part of any workshop, as it will ease the passage of wood over machine tables (i.e. thicknessers), lubricate saw blades and provide an anti-stick surface.

Suppose however, your tools and machine surfaces have become a little rusty...how best to clean up, assuming that they’re not so bad as to be a restoration project. One of the best products on the market is the Garryflex abrasive block, a pad of rubbery material impregnated with silicon carbide and available in three grades. Alternatively, I’ve used Liberon 0000 Steel Wool in the past, which is effective, but not as good as Garryflex.

Threads, as found on G-clamps and sash clamps, may also need some attention. Conventional oil, though excellent, is undesirable in a woodwork ‘shop as it will attract dust. The oil may also transfer to your hands, which is unquestionably not required when a delicate ‘glue-up’ is under way! A PTFE dry lubricant is the answer here and it’s also recommended for woodturning chucks.

Keeping the rust at bay isn’t difficult, but it does require constant vigilance before it becomes a serious problem. Regular, routine maintenance should be part of your ‘shop routine throughout the year and especially so regarding the ‘rusticles’ at this time of the year.

Hi,

I am Nancy Thigpen and welcome. I saw your post it’s very nice. Nice blog. I will keep visiting this blog very often. Thank you for our safety tips.