Timber Preparation | Squaring Timber By Machine

Timber preparation using a hand plane can a lengthy and fiddly process. If you are short on time, and want accurate results, then completing your timber preparation by machine with the help of a planer thicknesser is a no brainer.

What is timber preparation?

Timber preparation is one of the most important things to do after selecting your timber for your woodworking project, and is the process that ensures the wood is square and flat before it can be cut to size.

Having square timber is vital for ensuring your work pieces join together accurately and ensuring success in your woodworking project.

It is important to take your time at the timber preparation stage, as it will pay dividends later when it comes to assembly.

Cutting list

When selecting your timber you will have considered grain direction, flaws and other anomalies which may affect the way in which your project comes together. After selecting your timber you will need to prepare it to the size required from your cutting list.

The cutting list will feature the dimensions of every component you're going to need to make the project including the width, height and length.

But first you will need to prepare and square your timber.

Prepare timber for your project

There are two ways you can prepare your timber, either by hand using a hand plane, or by using machinery. In this article we explore squaring and preparing timber by machine, using a planer thicknesser.

Watch our helpful video guide, where our woodworking expert Ben Beddows shares with you tips, and shows you the techniques for squaring timber using a planer thicknesser. Or read our guide below.

Chose a face side and face edge

The first thing to do is to look at your timber and decide which will be your face side and face edge - these are the sides of your timber that will be visible. Flaws and blemishes may affect which sides you chose to be your face edge and face side.

Once planed square and flat, these will become the reference points for thicknessing and cutting the rest of your timber to size.

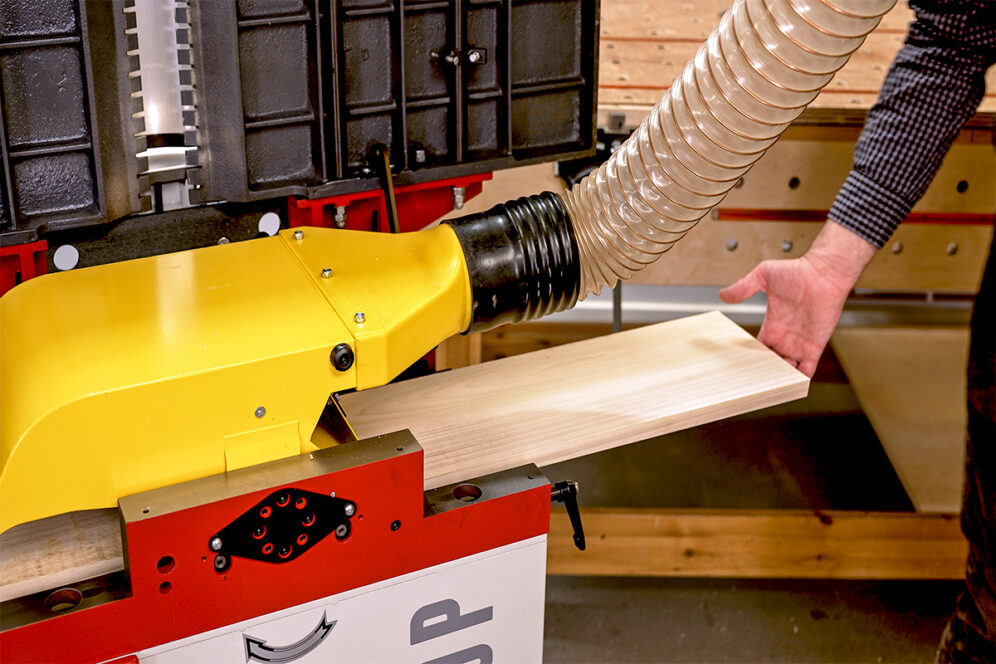

Surface plane your timber

Next, clean and level up the board. Your freshly sawn board will have surface saw marks and can be uneven due to twists in the wood. The process of surface planing will remove these flaws making the board smooth, flat and square.

Begin by machining the face edge and face side first. Make sure these are clearly marked.

Place your timber face side down and pass through the planer thicknesser taking a little off the surface each time.

Plane the face side

Once you have passed the board through the planer and flattened the face side, you will need to plane the face edge. First check your fence is square and at 90 degrees to the table using an engineer's square.

Before planing the face edge, pay attention to the grain direction and how the grain is leaving the edge of the board. Ensure you place the board into the planer following the grain direction. Going against the grain can cause the fibres to tear and will not leave a smooth surface.

Once planed, check each face is at 90 degrees to each other using a square.

Thickness your board

Next we need to thickness the board. The thickness you chose will depend on your project.

Convert your planer thicknesser into thicknessing mode.

Using callipers, measure the thickness of your board in several places taking the largest measurement to set the table height. This will mean on the first pass the cutter with skim the surface initially, before raising the table incrementally to reach the correct thickness of your required project.

Your board should now be square with the face edge and face side at right angles to each other, and the board thickness set to your requirements.

Cut to length and width

Once your face edge and face side are square, and your timber thicknessed, you can cut your board to size as per the requirements of your project and cutting list. You can use your face edge as a reference against fences on a bandsaw or table saw.

Timber preparation by hand

If you prefer to take your time and hone your woodworking skills, you may want to opt to square your timber by hand using a hand plane. The same principles apply, but the process is a lot longer. However, a hand plane is an inexpensive alternative and does not take up as much room in your workshop.

Whichever method you chose, learning to square your timber correctly and accurately is one of the most important steps to take to make your woodworking successful.