SawStop Focus | Festool TKS 80 Bench-Mounted Circular Saw with SawStop Technology

With the arrival of Festool's new TKS 80 bench-mounted circular saw, serious injuries while sawing will become a thing of the past. The SawStop technology works to protect your most valuable tool - your fingers - from harm and injury which means sawing has never been safer!

According to Festool, the statistics from the German Social Accident Insurance (DGUV), Accidents at Work 2017 states approximately 4,000 injuries are caused by circular saws annually. This equates to 16 injuries per working day which causes a massive impact on productivity, potential earnings and personal ability to work, especially if self employed. The TKS 80 bench-mounted circular saw with SawStop technology is a game changer when it comes to protecting what matters the most. Read our helpful guide to find out more!

Key Features & Benefits of the Festool TKS 80

Integrated SawStop Technology

Firstly, enjoy increased safety while you saw with the first Festool saw with innovative SawStop technology. This guarantees safe sawing in non-conductive materials.

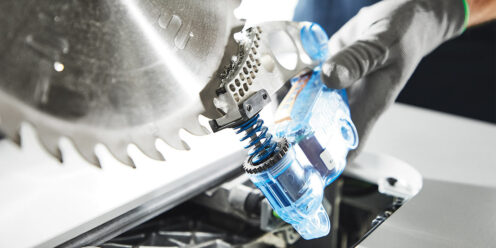

Intelligent Cartridge

A cartridge releases a pretensioned spring and pushes an aluminium block into the saw blade. After being triggered, the cartridge is replaced in just a few steps.

Flexible Working

Thanks to the angle stop you can take advantage of several features. These include a work surface that can be extended in both its width and length, improved flexibility and the chance to enjoy variable work, even with large workpieces (up to a cutting height of 80mm).

Responsive Sensor

The saw stops within 5 milliseconds upon contact with the user's skin and disappears into the work surface.

Bypass Option

If necessary, the SawStop technology can be deactivated. In such instances, you can machine conductive materials such as copper and aluminium.

Maximum Precision

If you carry out mitre rip cuts, you'll notice fewer splinters on the upper surface of the material when you swivel the saw blade to the left. Plus, if you use the splinter guard, enjoy clean precise results, even on the underside of the material. With a fine adjuster and various locking positions, the saw can also be used for both rip and cross cuts.

Comprehensive System Accessories

For convenience, your work surface can be extended in both its length and width. The sliding table allows for cross-cuts up to 920mm.

Space Saving Solutions

A tool garage attached on the side provides optimal storage space for saw blades, cartridges and push sticks.

Choose Your Options

Festool TKS 80 EBS- Set

Purchase the complete set which includes:

- HW universal saw blade W40

- 3x splinter guard

- Angle stop

- Dust extraction set

- Workpiece holder

- Operation tool

- Extension table

- VB TKS 80

- Guide extension VL TKS 80

- LA TKS 80 stopper

- Sliding table ST TKS 80

Alternatively, purchase the TKS 80 EBS and buy the accessories you need, as and when you require!

Festool TKS 80 EBS

This includes:

- HW universal saw blade W40

- 3x splinter guard

- Angle stop

- Dust extraction set

- Workpiece holder

- Operation tool

KT- TKS 80 Replacement Cartridge

The replacement cartridge contains the central element of the TKS 80: SawStop technology. After being triggered, the cartridge must be replaced which is simple to do.

VL TKS 80 Guide Extension

Purchase the guide extension to extend the support area by 580mm. Easy and quick to assemble and dismantle, the extension allows you to safely and precisely saw to length. Comes complete with adjustable dimension scale.

LA TKS 80 Stopper

The moveable stop profile with fine adjuster allows for precise rip cuts. It features a front operating lever as well as a clamp for secure mounting on the bench-mounted circular saw.

ST TKS 80 Sliding Table

For large work areas, the sliding table can be installed in two positions. Ideal for cross-cutting with a cutting width up to 920mm, it comes complete with four plastic rollers to ensure that the sliding table moves smoothly.

VB TKS 80 Extension Table

With an adjustable dimension scale, the extension table is simple to assemble and dismantle. It provides safe and precise width sawing and extends the support area by 411mm. Use to achieve a maximum cutting width with 680mm rip cut.

Circular Saw Blades

Made from high-quality steel with saw teeth made from fine-grade carbide, Festool circular saw blades are designed for the toughest conditions. Colour coding makes it easier to select the correct saw blade for the application.

Discover more…

If you’ve enjoyed reading this article, why not take a look at other Festool articles? Firstly, the Festool CTM MIDI M class dust extractors are perfect for when you’re on the go. Ideal for extracting M dusts on the construction site with minimal impact on health, the extractor is low weight and features compact dimensions and a host of innovative details. Read our informative Insights guide to find out more.

Next, our helpful guide on the Festool KAPEX KS 120 mitre saw details its fantastic features. Designed for more efficient working and more accurate results, the KAPEX KS 120 makes perfect cuts again and again and can tackle the most demanding applications on site or in the workshop.

Not found what you're looking for? See all Festool articles here.

Get in touch!

If you’ve invested in the Festool TKS80 Circular Saw with SawStop Technology, we’d love to hear from you. Comment below or send us a photograph and tell us all about your purchase. Alternatively, get in touch via our social media platforms. Find us on Facebook or connect with us on Instagram and use #sawstop to @AxminsterTools.

Please advise blade size and arbour diameter of festool Kapex KS 120

Hello, thank you for your question. The blade diameter is 260mm and the bore is 30mm.

Will we here in the USA be able to buy the table TKS 80

Do you have any info on the accuracy of the fence and mitre fence. I am concerned about making perfectly angled cuts and can't see any explicit info on how to set the fences accurately.

Hello there, many thanks for your question. Please see below some information from Festool which should help.

The rip fence can be adjusted if necessary, but is normally perfect from factory set-up.

1. Set the fence on the saw table and lock up the large black knob just under the front of the fence.

2. Loosen the four Allen key screws under the front of the fence (the rear of the fence will now move).

3. Place a set square on the table to the fence and line up the square to the fence and make sure this is perfect.

4. Once square to the table, turn the lever on the front of the fence that actuates the rear locking plate at the rear of the table.

5. Lock up the four screws under the front of the fence and set-up is now complete.

The side fence can be adjusted if necessary but again is normally perfect from factory set-up.

1. Lock the large round knob just under the front of the angled fence.

2. Loosen the two flat head screws and also the black thumb screw knob on the top of the fence. The fence will now swivel.

3. Again using a set square, set the square to the edge of the table and line up to the fence.

4. When square, lock the black thumb screw and lock the two screws.