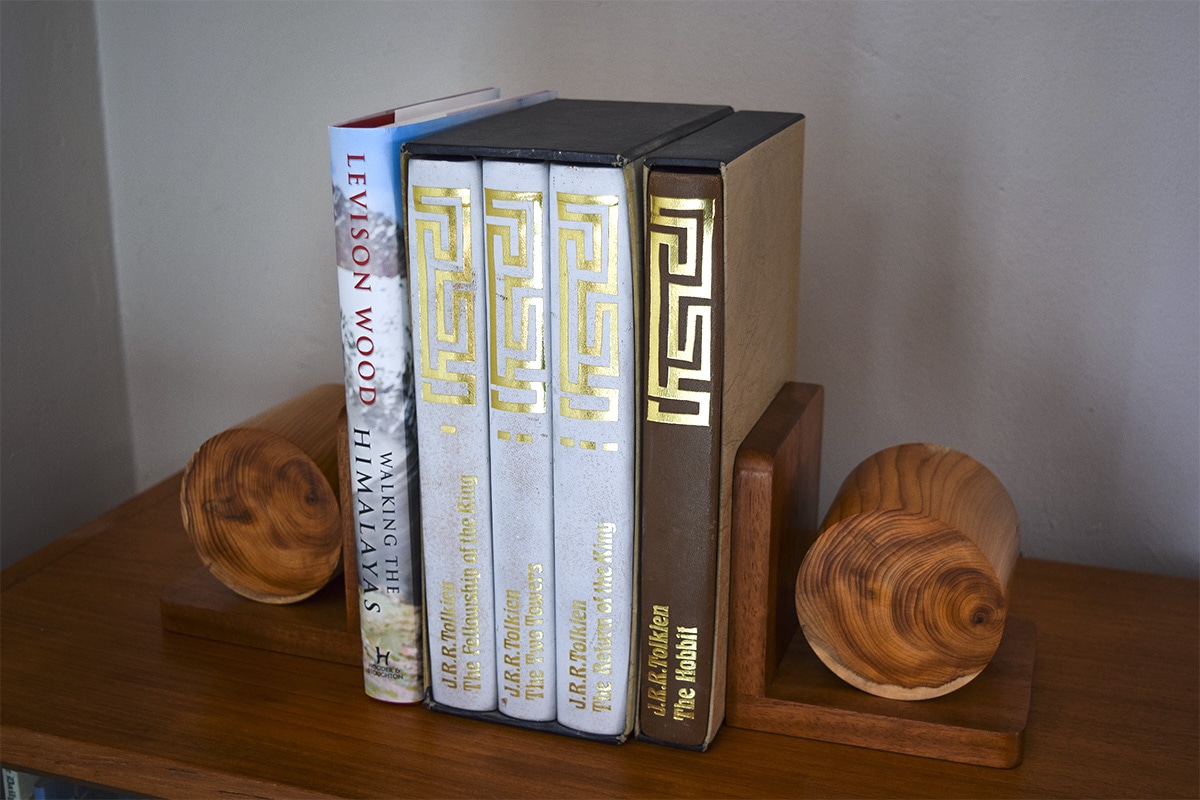

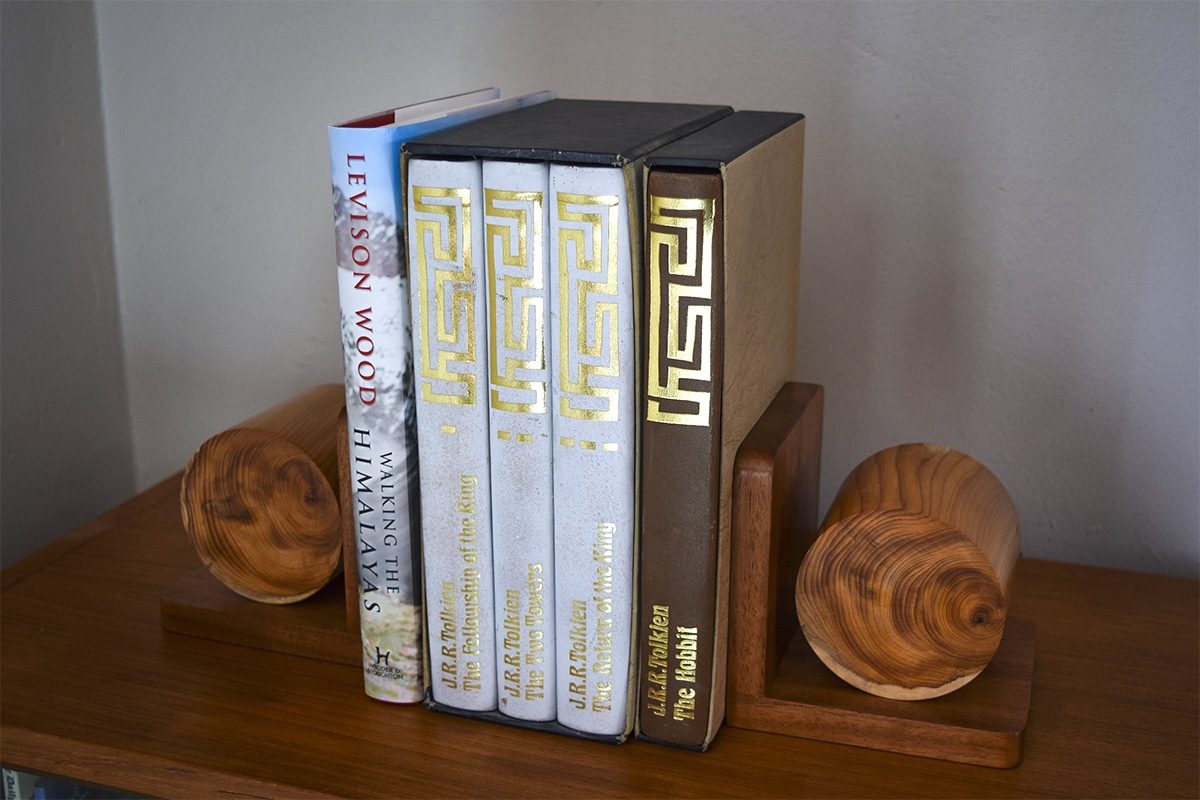

How To Make Wooden Bookends

Combine traditional joinery with traditional woodturning to create bespoke wooden bookends. With handmade dovetail joints finished with wood turned detailing, these bookends will look impressive on any bookshelf.

What you'll need

Make the Wooden Bookends- A Step by Step Guide

Step 1

Select four pieces of wood, ends prepared square. This guide uses lengths of 120mm x 105mm x 16mm and used mahogany but any hardwood can be used.

Step 2

Start by marking the joint shoulder lines with a cutting gauge or knife and a try square on the 4 sections of wood.

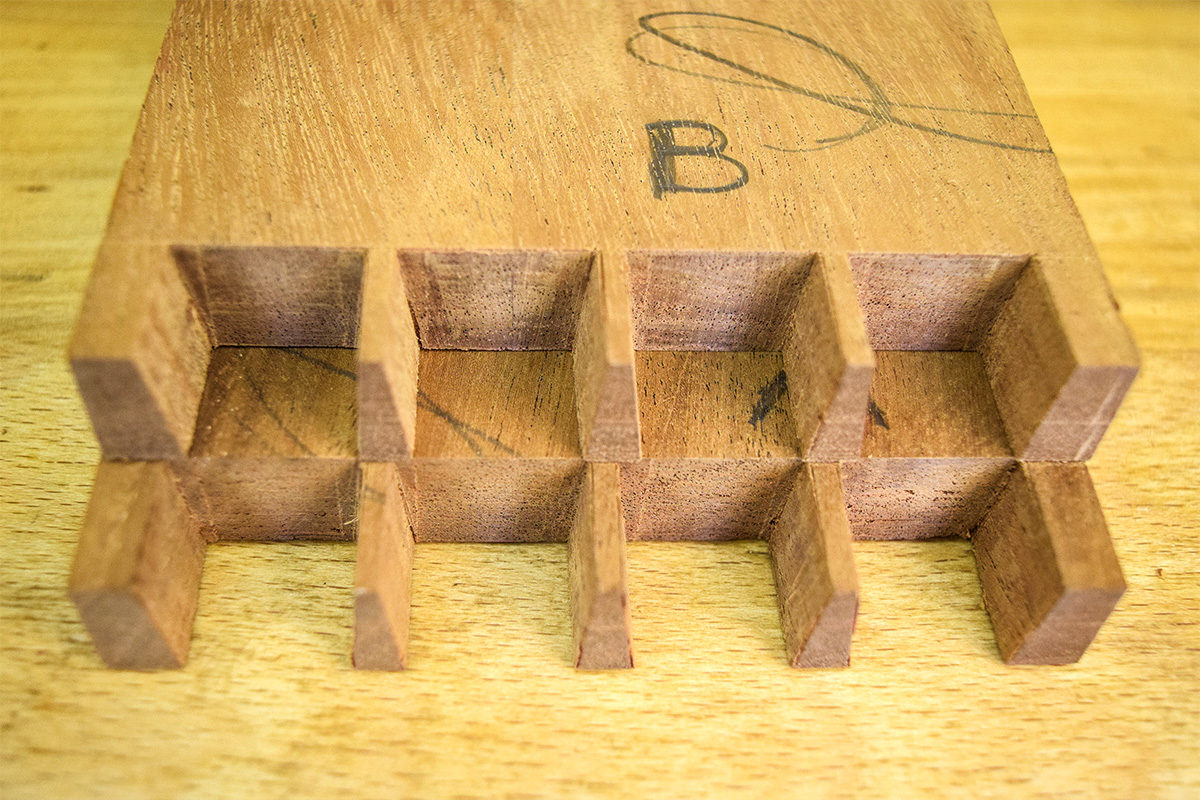

Step 3

Then mark out the dovetails and cut the tails, removing the waste with a piercing saw.

Step 4

Chisel to the shoulder line using a scrap square block and clamp to a bench.

Step 5

Label the joints and mark out pins, using a jig if required, complete marking out the pin boards.

Step 6

Cut out the waste and chisel to the shoulder line as in steps 4 and 5.

Step 7

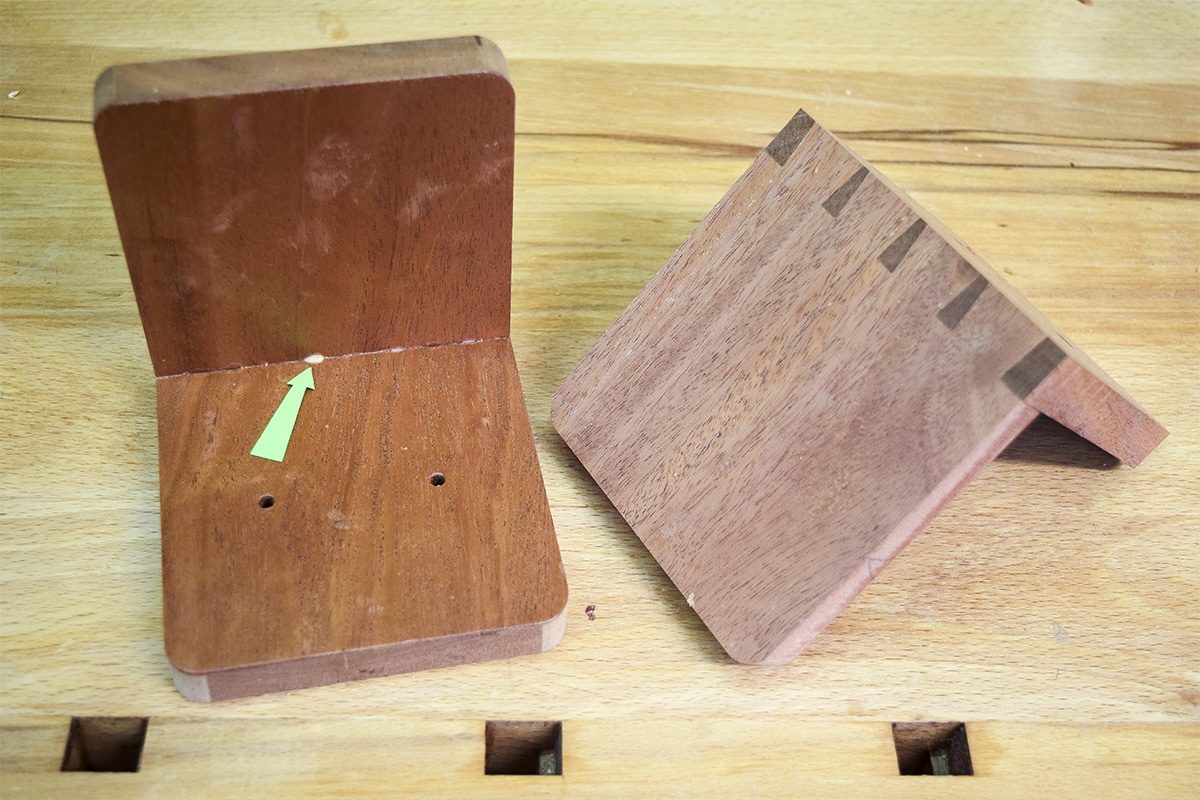

Trial fit the joint by pushing it half way in.

Step 8

On the two base sections, mark out four holes for screws (arrowed) and drill 4.5mm holes and countersink the underside. Round off the corners equally and shape the corners on a disc sander, so no sharp edges are left

Step 9

Sand all internal surfaces to 240 grit, mask off the joints and polish with two coats of Liberon Sanding Sealer using a white cloth (as a coloured cloth may taint the polish).

Step 10

Wax surfaces with clear wax polish and buff with a soft cloth.

Step 11

Glue the joints together and leave to set. The wax acts as a ‘resist’ enabling any excess glue to be easily removed once set.

Step 12

Clean up dovetails with a fine set smoother. Protect the inside faces with leather jaw liners and cover the bench with similar. Sand exterior surfaces to 240 grit using a Mirka hand sander and Abranet abrasives.

Step 13

Finally, detail sand the edges and corners with 240 grit Abranet and a cork block. Polish the exterior surfaces as in step 9 and set aside the bookends.

Step 14

Further to this is to wood turn the round detail of the bookends. Mount the block of yew securely in the lathe and set to very slow speed. Gradually turn the wood blank to a cylinder, increasing the lathe speed as the waste is removed. When the yew is round and to your desired size for the bookend, sand to 320 grit and part off into two sections 80mm long. Clean up ends on the disc sander and with Mirka Abranet abrasives. Leaving you with two completed cylinders for the bookend detailing.

Step 15

Grip each cylinder in a vice, draw a line down the centre and mark off the hole positions (arrowed).

Step 16

Then, drill a small pilot hole and polish the cylinders as steps 9 and 13.

Step 17

Finally, assemble the cylinders to the bookends, with 4mm x 40mm screws. The bookends are now ready for the shelf.

"Mahogany at 120mm x 10.5mm x 16mm" ? Is this me or are these dimensions wrong.

Probably. At the moment I'm sunning myself on a hot beach in Mauritius with a cold beer for company, so I've got other 'distractions' to concentrate on. Life's tough, but someone's got to do it!