Atelier Cabinet Makers Review Axminster's Planer Thicknesser

We’ve invited the owners, designers and makers of Atelier Cabinet Makers, to tell us more about the Axminster Trade planer thicknesser and spiral cutter block. Since recently purchasing the machine from Axminster, Jamie shares why they’ve opted for this machine and what they like most about it.

Delivery and set up

We took delivery of our new planer thicknesser back in October 2017. It arrived pretty much fully assembled, minimising the work involved in getting it up and running. The first thing you have to do is remove if from the delivery pallet. We managed this fine between Rhiannon and myself.

We already had an Axminster mobile base that we resized before aligning next to the new machine (whilst still on its pallet). We then wiggled the planer thicknesser bit by bit to gently drop it down from the pallet and into the mobile base. Both cast iron tables come already fully fitted, leaving you to fit the fence and bracket/tilt mechanism along with the blade guard, fence storage and smaller components.

Best instruction manual for a machine that I have come across so far!"

The whole process of getting set up took less than an hour. I found we only had to do minimal fine-tuning of the tables, which is all brilliantly explained in the instructions; the best instruction manual for a machine that I have come across so far! It’s full of large coloured photographs with explanations and couldn’t be easier to follow. It looks more like a magazine.

First startup

The first thing you'll notice when you start up the spiral cutting planer thicknesser is the exceptional reduction of noise compared to a straight knife machine. It's said to be up to 50% quieter, which for us is definitely agreeable since we can now talk without raised voices with the machine running. It is even quieter than our dust extractor!

What about the finish?

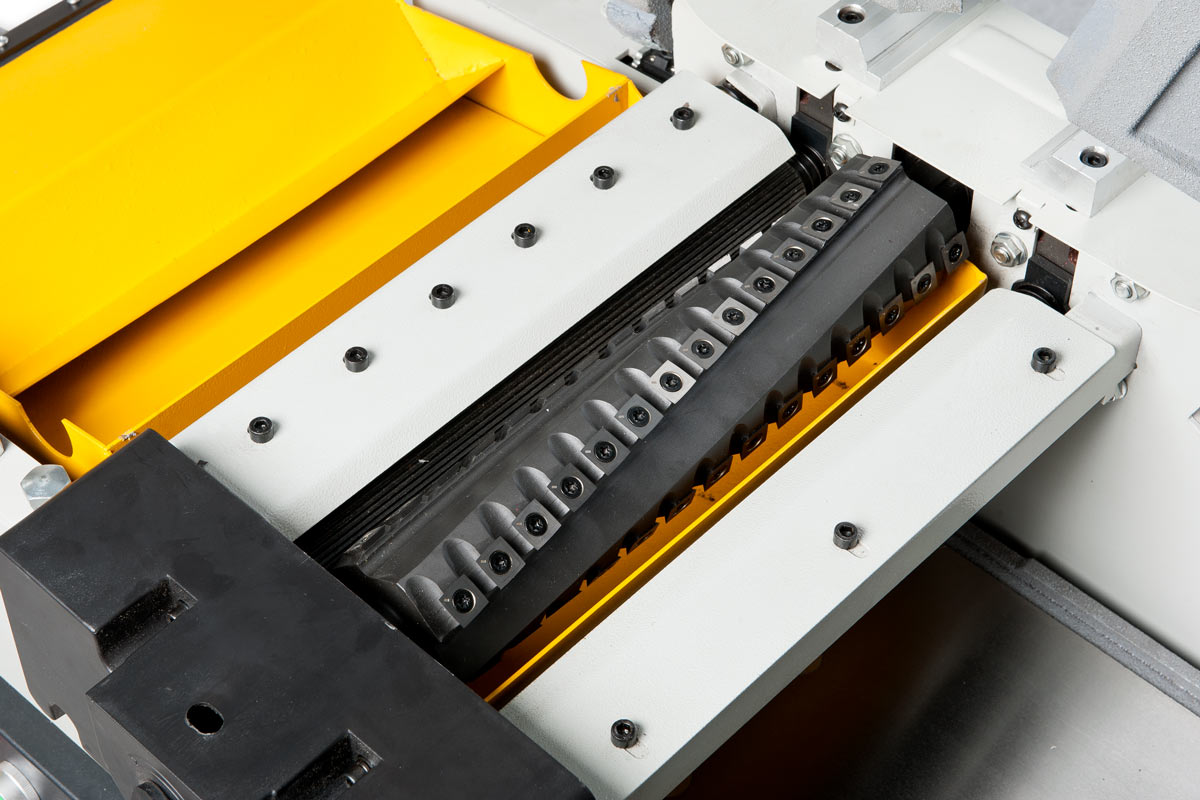

The spiral cutter block leaves an outstanding quality finish of cut. It doesn’t struggle with the difficult change in direction of the grain in timber. Also, there is no tear out like our previous straight knife machine. This is down to the way the cutters are mounted to the spiral block. Firstly, each cutting edge is ever so slightly convex (you can see this when you look at them). Pairing this with the mounted cutting angle enables the machine to give a shear cut through the timber with less stress, therefore prolonging the life of the machine and saving energy.

Benefits of the carbide cutters

Some of the benefits of the carbide cutters are that they are much stronger than the standard high-speed steel knives. So much so that the carbide cutters will stay sharp for up to ten times longer. Each cutter has four cutting sides, so before you actually fully replace the entire cutter set, you'll rotate the cutter until all four sides have been used.That gives you up to forty times longer than the time you would have before swapping and re-sharpening a set of standard HSS straight knives.

Stay sharp for up to ten times longer"

The carbide cutter sets are not cheap, looking at just over £400 for enough to replace the entire set. But you would have to compare this to the cost of 40 resharpens of a set of HSS knives. With the effort and time involved in this alone, the carbide cutters are a win for me!

The carbide cutter sets are not cheap, looking at just over £400 for enough to replace the entire set. But you would have to compare this to the cost of 40 resharpens of a set of HSS knives. With the effort and time involved in this alone, the carbide cutters are a win for me!

Think about that time that you put a freshly sharpened set of straight knives in your planer, and within no time you’ve hit a staple or similar, and now have a chip in your fresh blades set. Back to the sharpeners they go or spend forever sanding out that irritating raised groove from everything you thickness after that event. If this hasn’t happened to you yet, it’s quite a common event for woodworkers. Now with the carbide cutters, you will have the ability to rotate just the affected cutters and get back to thicknessing and enjoying the clean finish of your timber. For convenience, each carbide cutting edge is numbered from 1-4 so that you can keep track of when a cutter needs fully replacing.

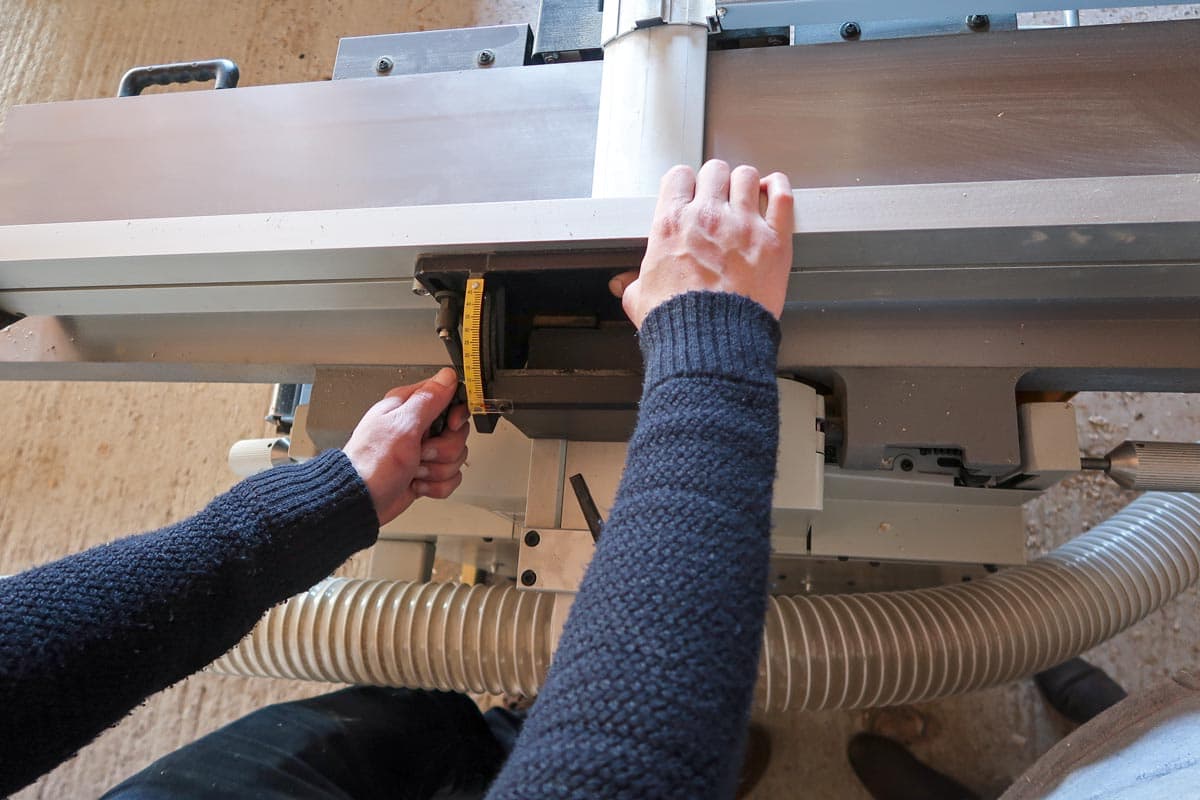

Simple cutter alignment

When you come to changing the entire set of carbide cutters, you will be doing so with ease. Where the straight knives each need specifically setting, using jigs or measuring tools (not to mention the sometimes difficult to reach small tightening screws) the carbide spiral block cutters simply remove one by one with a Torx key. The new cutters align themselves to their designated position for you to replace their individual Torx screw. We've had our machine for five months now and we've not had to replace or reposition any of our cutters yet. I wish we had a measure of the number of meters of timber we’ve fed through our Axminster trade series planer thicknesser just to know how well it's performed.

Switching from planing to thicknessing is simple"

One of the most important things for me is ease and speed of changing to and from planing and thicknessing modes. In my dream workshop, I would have space for a stand-alone surface jointer and also a thicknesser. With Axminster’s ATPT129, I can easily change from either mode and be fully set up in the other in just minutes. This is very convenient as with some jobs I need both setups frequently.

Switching from planing mode to thicknessing as a process is simple. Firstly, remove the fence and place it on the storage rack at the back of the machine. This is brilliant, as our older version didn’t have this, it's more convenient than finding a space in our busy workshop. Next, unlock the planing tables with the locking levers. This enables the tables to each lift up and stand out of the way, where they are held by a safety catch. You can now flip the large chip extraction hood in to place and click it into the thicknessing mode position. Release the locking lever on the front of the machine to engage the thicknessing function, set your thicknessing cutting depth and you’ll be ready to go. Changing back to surface planing is pretty much the reverse of these steps. One thing to note is that you do need to drop the thicknessing table to 150mm to swing the extraction hood back down for surface planing.

Surface planing

When surface planing, the large tables (totalling 1380mm in length) provide a brilliant support for planing larger and longer stock. I like to use an additional support on the outfeed side for extra ease. The alloy fence is long and rigid, with tilting ability of up to 45 degrees for bevels. I initially thought I would prefer a cast iron fence, but have had no complaints with the alloy. The massive bonus is the reduction in weight compared to a cast iron version. This is appreciated when switching to thicknessing on a regular basis and removing the fence a lot. If surfacing wide stock, there is a real noticeable difference compared to our old machine in the smoothness of cut and no vibration that we used to experience, reduced by the shear cutting action. The new Axminster planer thicknesser also has a lower surface planing table height. This increases support when edge planing wider boards, doors or worktops. In surface planing mode the max depth of cut is plenty for me at 4mm.

The importance of being mobile

As I mentioned, we keep ours on one of Axminster’s mobile bases. This is to enable easy manoeuvrability in our workshop, which doesn’t have the smoothest of floors due to being an old dairy farm building. The planer thicknesser weighs in at about 270kg and the mobile base has no complaints when I am pulling and pushing the machine around the workshop. I highly recommend these, particularly if you have a small workshop.

-

Axminster Professional Planer Thicknesser Mobile BaseFrom £199.98 £166.65

Extraction

The dust extraction is said to be better with a spiral cutter head machines due to the shear cut. This gives smaller sized chips rather than the longer chips and strips you can get from a straight knife machine. The smaller chips, being lighter, flow easier, faster and reduce the chance of extraction pipes clogging. Though I have to add I had no complaints with the extraction on our older straight knife machine either!

Conclusion

I would highly recommend one of Axminster’s planer thicknesser machines and definitely the spiral cutter head version. This machine would sit happily in the workshop of a hobbyist woodworker, through to a small business workshop with 2-3 people using the machine on a daily basis. If you're in the market for a new planer thicknesser, be sure to visit one of Axminster tools showrooms to take a look at this machine in person. I’m sure it would not disappoint!

Watch Jamie and Rhiannon in our Meet the Maker series.